Now I’m going to turn it over to Jarrett who will go into detail on the aspects of tire studding.

Key Factors Affecting Tire Performance by Jarrett King

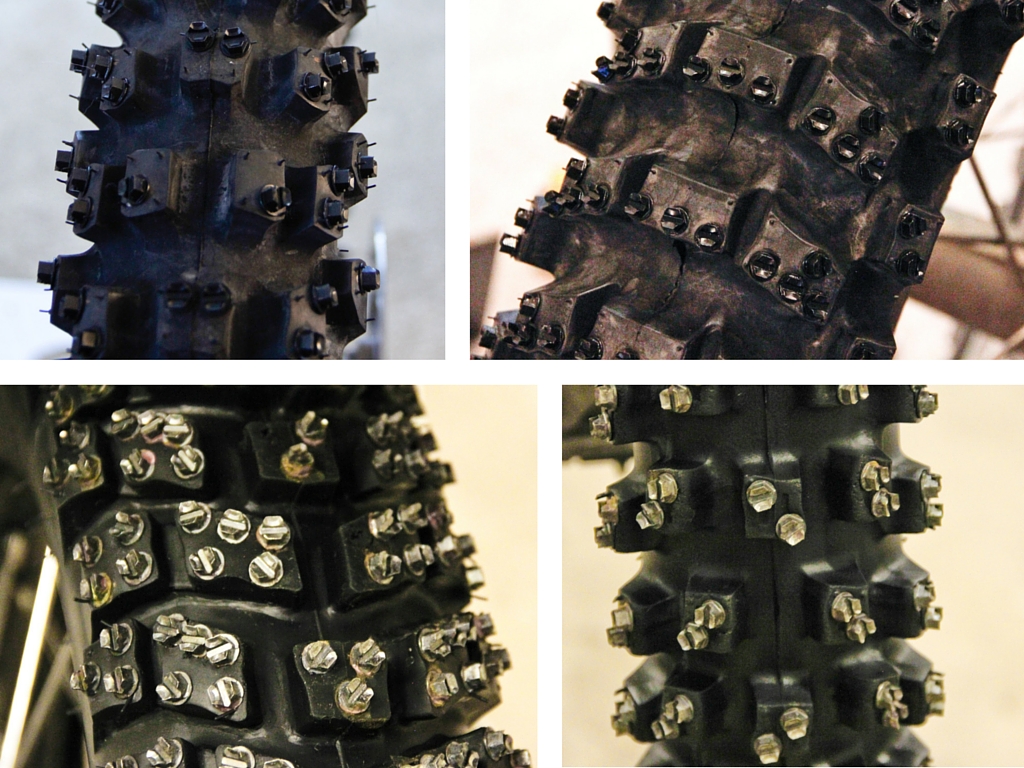

Tire Choice: Selecting the right tires to stud is critical in terms of traction and tire life. Lug height, tread pattern, carcass thickness, and rubber composition all have a huge influence on how well a tire will work. Unfortunately, there is not a lot of data supplied by tire manufacturers available to help guide a person in the right direction, but there is plenty of empirical data floating around amongst the ranks of ice riding enthusiasts. To help get you started I put together a list of the most common ice tire choices.

Front Tires

Mitas Ice King - (Top Left)

Bridgestone ED11 - (Bottom Right)

Rear Tires

Mitas Ice King - (Top Right)

Kenda K335 - (Bottom Left)

Motoz X-Circuit - (Not Shown)

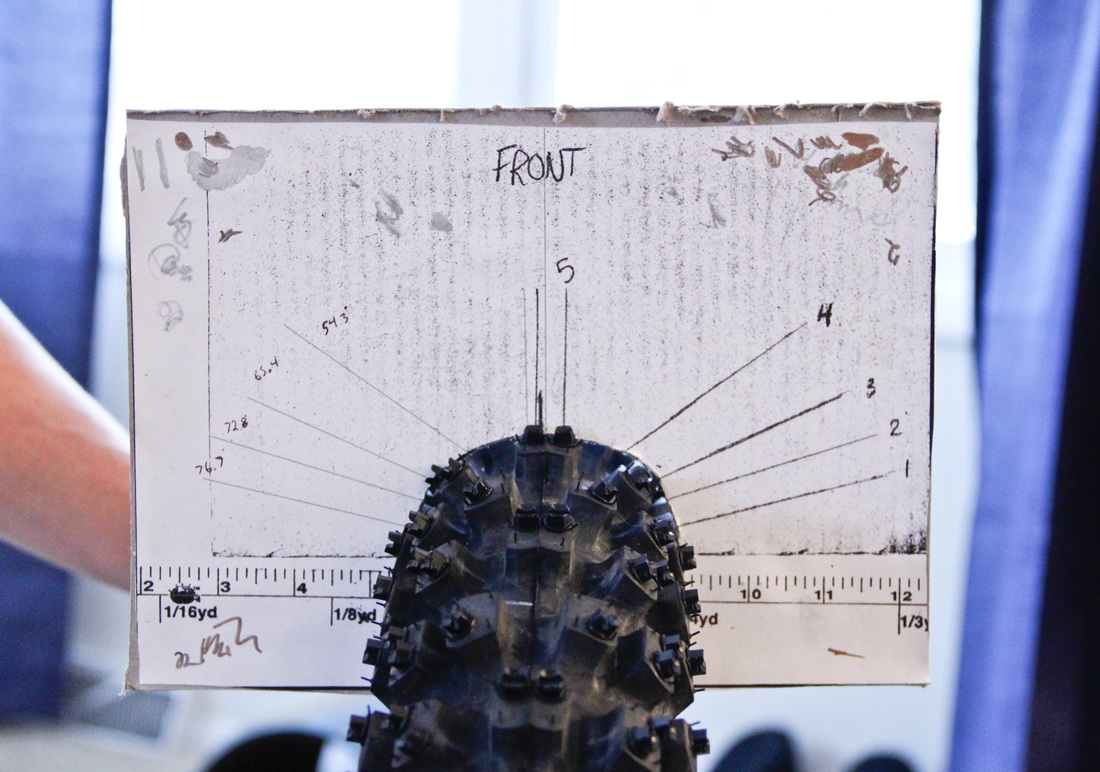

Pattern: The pattern in which the screws are laid out on the tire has a huge influence on the traction and grip characteristics of the tire. Specific patterns may be tailored to provide more grip or slip depending on the rider and how the tire is used.

Screw Type: AMA or Canadian style screws are the primary options for competitive ice racing. The two screw types are defined below:

AMA screws - 3/16” head height, sizes #8 or #10, and range in length from ⅜” to 1 ½”

Along with the screw requirements for the different racing classes, keep in mind purpose made ice screws go through a different hardening process than normal hardware store screws, allowing them to stay sharp longer. If you’re going to stud a pair of tires and want longevity, be sure to use a good quality screw.

Screw Threads: Fine thread screws are preferred because they do less damage to the rubber during installation. They are also easier to set to the correct height when fine tuning the screws.

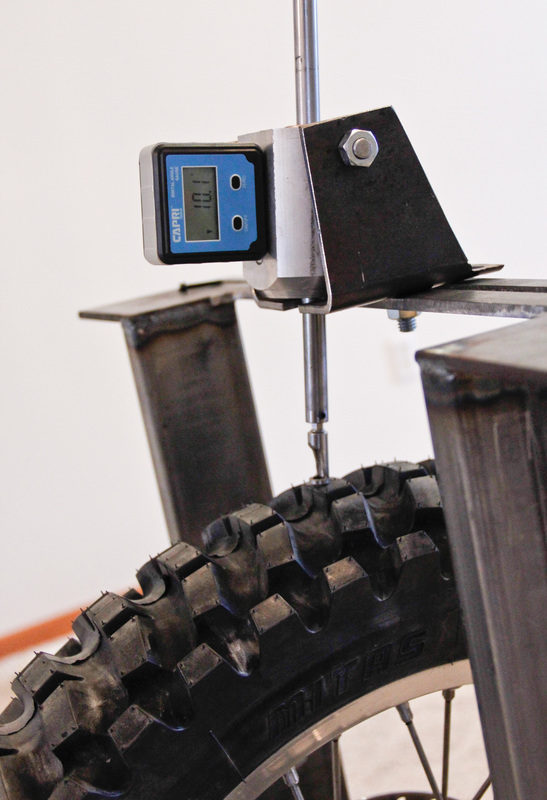

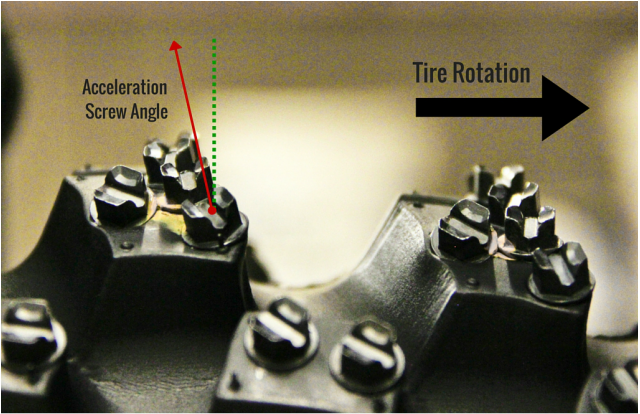

Screw Angle: The angle the screw is driven into the tire dictates how the screw contacts the ice. The screw angle can be broken down into two parts, the fore/aft angle, and the side angle.

- Sweep: Tire builders refer to the fore/aft angle of the screw as the sweep angle. Ideally only the leading edge of the screw should make contact with the ice. This can be achieved by angling the screw anywhere from 10 to 30 degrees upon installation

- Side Angle: Screws used to grip the ice when the bike is leaned over will be installed at an angle which complements the contour of the tire.

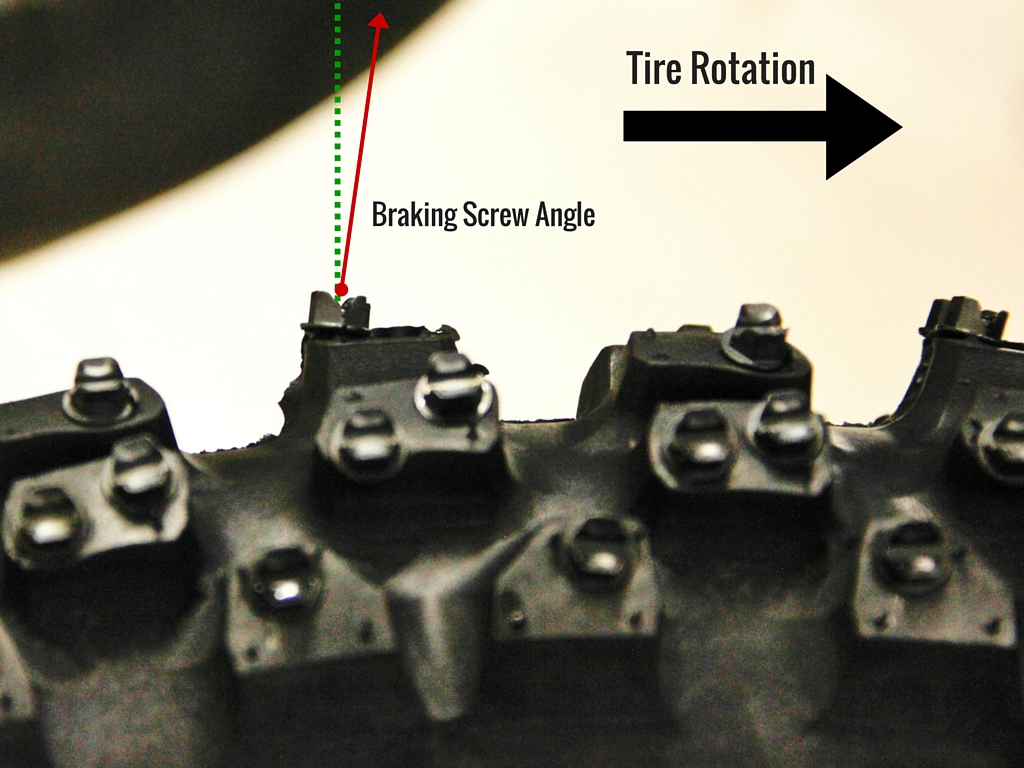

Braking Screws

Braking screws are at the rear of the lug on top, but when they are on the ground they are on the leading edge (biting edge) when under braking, thus the name “braking screw”. Sweep is used to prevent the screws from chattering on the ice under braking because of the fact that the crown would strike the ice at two points if installed flat. The magic sweep angle is the shallowest possible angle without the “rear” part of the screw crown biting in. With Canadian screws, this angle is much more straight up and down but still usually has 10 degrees or so. If you leaned them too far forward it will damage the knobs because the screw isn’t sunk into the liner enough, if you went straight in they will function but it makes the tire feel a bit strange under heavy braking.

Again, there are differences between AMA and Canadian screws. The Canadian screws can go virtually straight in, AMAs need that biting edge so they don’t deflect or lose traction because of two different contact points. Picture a skate blade. The more sharp and precise the edge, the more ground pressure is focused on that area. Same with screw tips, if two parts of it hit the ice it will start to “float”. Optimal angle is shallowest possible (as close to straight up and down as possible) before the back edge of the screw starts touching the ice surface.

Cornering screws are typically run in at one angle, there is no sweep to them. Some builders have tried adding some sweep, however, never with too much angle. If you run an ice tire over a piece of cardboard under lean you will see that the top edge of the screw is contacting the ice at an angle that prevents the front tire from low-siding. In essence these screws do the exact reverse thing that the rear tire does under acceleration.

Jarrett: When it comes to general screw pattern and arrangement, there are a couple things to consider. First, is that on the rear tire the inverse “V” pattern is there for a reason… what it does is each screw passes the load onto the next screw while under lean (picture them passing sandbags to each other). To prove this, reverse a V-pattern tire, it will be all kinds of squirrely under acceleration and then the rear will try to jump out from under the bike when you hit the brakes, it’s truly scary.

My second point, ideal screw pattern is a balance between a few different factors. Knob spacing, contact pressure and knob count/pattern. On a tire like a Kenda, so many screws are striking the ice at once that the tire is floating on the surface of the ice. Traction is being gained by getting the maximum number of screw heads to hit the ice at the same time. This is great until the moment that there is a hint of snow on the lake and the tire begins to act like a crazy carpet under the bike. It floats because it can’t maintain ground pressure.

The old Pirelli Lagunacross tire became amazing the moment that Marcel Fournier came out with the modern Canadian Ice screw. The knob pattern was ideal (V shaped paddle) for the application and the knob spacing was super wide, which meant great ground pressure on each screw. Unfortunately that also meant a much larger radial load on the screws and knobs which often lead to premature knob or screw failure. The Mitas Ice King does not generate the same ground pressure as the Pirelli because the knobs are quite a bit closer but the tire’s compound and knob pattern allow for a much better balance of ground pressure (traction) to durability ratio. Using AMA screws, a Mitas Ice King does not benefit from additional screw rows the way that a Kenda will because it will float much quicker, but without as many screws contacting the ice.

Ice tire building is a compromise. The perfect ice tire doesn’t exist in the same way that there is no perfect Intermediate MX tire… but there are some that are MUCH more effective than others.

My third and final point, ice tires have been built in north America since the early 30s. The angle of screws is something that has been tried in multiple arrangements hundreds of times over. For someone getting into the sport their enthusiasm may make them believe that changing things will create a magic setup, but the reality is that a true set of wheels (no dings dents, warps), with consistent screw angles and heights, proper air pressures, and properly balanced is the most effective way to kick ass out on the ice racing track. Oh and don’t forget to duct-tape that face (frostbite sucks!).

Paul: I hope you all found Jarrett’s info on ice tires beneficial. In Part Two, we’ll get into the details of mounting ice tires. If you have any comments or want to share some info please leave a comment below.