I’m going to discuss the importance of criss-cross patterns, tightening sequences, incremental steps, and joint lubrication but first I want to explain how a bolted joint works. As a bolt is tightened to secure a pair of parts, the bolt will stretch a very small amount. The stretch in the bolt creates tension or preload in the joint which is the force that keeps the joint together. The amount of preload created is dependent on bolt size, bolt material, the torque applied, and the friction between the threads. There are additional variables, however a discussion on bolt engineering would be very long and not all that exciting! As long as you understand the basics for engine building you can begin to appreciate the importance of correctly tightening fasteners.

As you are well aware, an engine consists of many parts fastened together. What you may not consider as much is that the majority of these parts are fastened by more than one fastener. This means that how much you tighten/preload one fastener will have an effect on the surrounding fasteners. This interaction between the fasteners begins to shed light on why tightening sequences are so important.

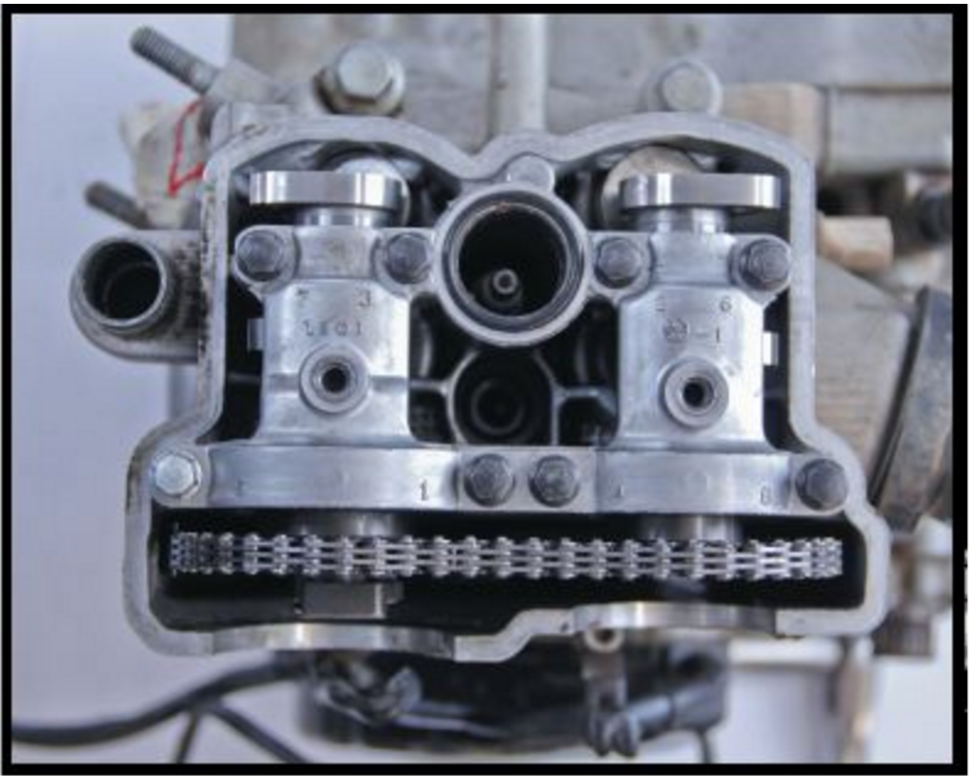

The evenness of the preload across the bolts securing a part can affect part life. Warpage can occur in parts which are improperly tightened, ultimately rendering the part useless. A prime example of a part that can warp is a four-stroke cylinder head. If the bolts are unevenly tightened over time, the cylinder head can become permanently distorted. Gasket sealing problems can also occur from improper preloading of bolts across a part. In order for a gasket to seal it must be evenly compressed. If one area of a gasket is highly compressed and tensioned while another area is not, the gasket can easily leak through the low tensioned area. In the case of plain bearing bores, such as the cam cap, uneven preloading may cause the bearing bore to distort. As a result the cam may become difficult to turn. Or if run, the cam bearing bore will wear unevenly and in severe cases the cam could seize.

While ensuring bolt preload is even can be a problem there are three tightening techniques that virtually eliminate the issue. If you’ve been building engines for any length of time you’ve probably already been utilizing these techniques. Hopefully now you may have a better understanding of why the service manual instructs you to tighten parts a specific way.

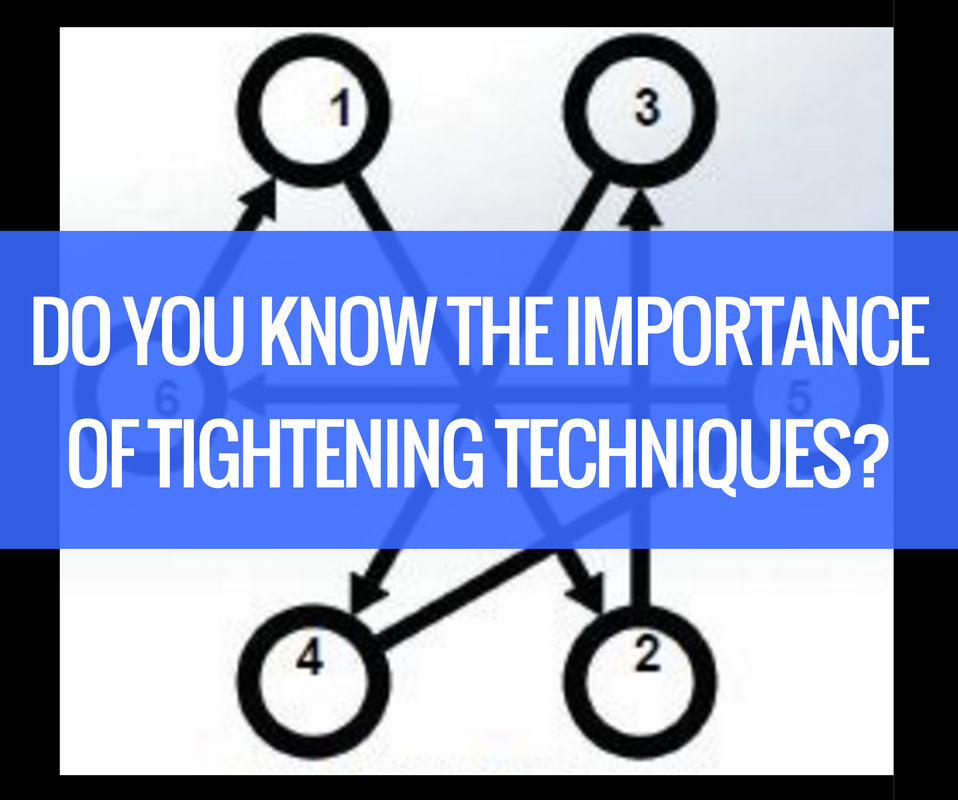

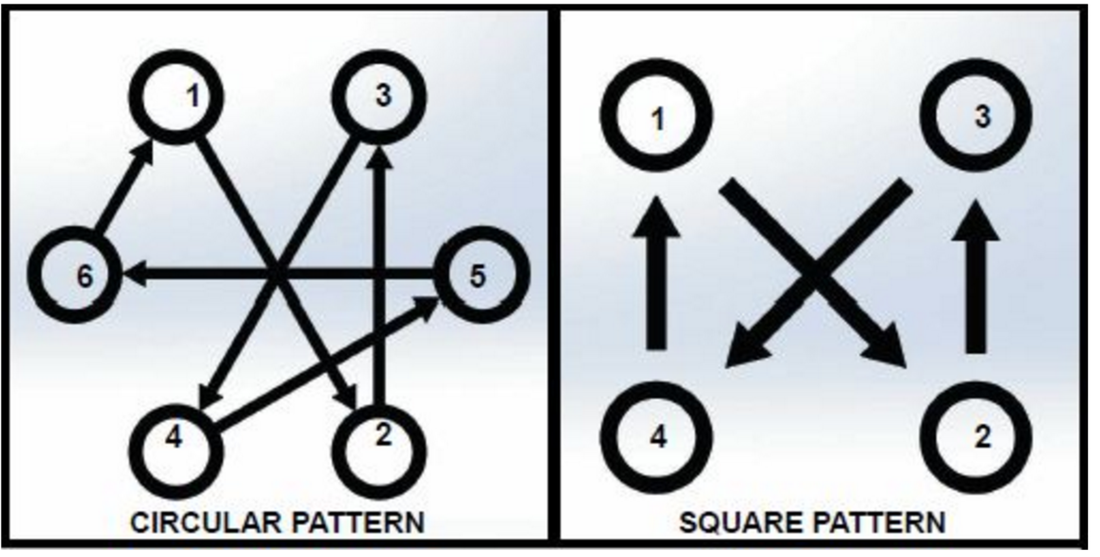

Criss-Cross Patterns

Criss-cross patterns are called out when tightening or loosening parts with a simple square pattern or circular bolt pattern. These basic patterns have been around for a very long time and are a proven method for evenly distributing clamping load across a part. Most cylinder heads will utilize this type of clamping pattern.

For more complex bolt patterns, such as those found on cam carriers and crankcases, the manufacturer will usually identify a specific sequence for tightening and loosening the fasteners. This sequence is based on testing and the past experiences of the manufacturer.

Highly torqued bolts, such as those found on the cylinder head, are almost always tightened and loosened in incremental steps. An incremental tightening sequence consists of torquing all the fasteners to a specific torque value, then increasing the torque and tightening again, and finally arriving at the final torque value. This sequence is typically performed in two to three steps.

Here’s something important to keep in mind regarding incremental steps! When torquing bolts in steps the change in torque between the steps must be large enough to induce bolt movement. For example if a bolt was torqued to 35Nm at the first step and the second step was 38Nm this would not be enough of a change to make the bolt move at the second step. The torque wrench would not overcome the friction of the stationary bolt and would hit 38Nm before the bolt even moves. As a rule of thumb incremental changes should be no less than 5Nm and if possible should be greater.

Lubrication

For highly torqued fasteners often times the service manual will specify that the threads of the fastener must be lubricated. The lubricant can be as simple as fresh engine oil or a specifically formulated thread lubricant product.

| I hope you enjoyed this quick summary of tightening techniques and their importance! If you have tips of your own you’d like to share or other pearls of wisdom please leave a comment below. For those of you interested in more engine building knowledge check out my book, The Four Stroke Dirt Bike Engine Building Handbook. You’ll find more detailed and comprehensive info on engine building there. US shipments can still reach your stocking in time for the holidays if you order within the week! Be sure to use offer code rebuild2016 and receive 15% off at checkout. Click the button below to learn more. Thanks for reading and have a great week! |