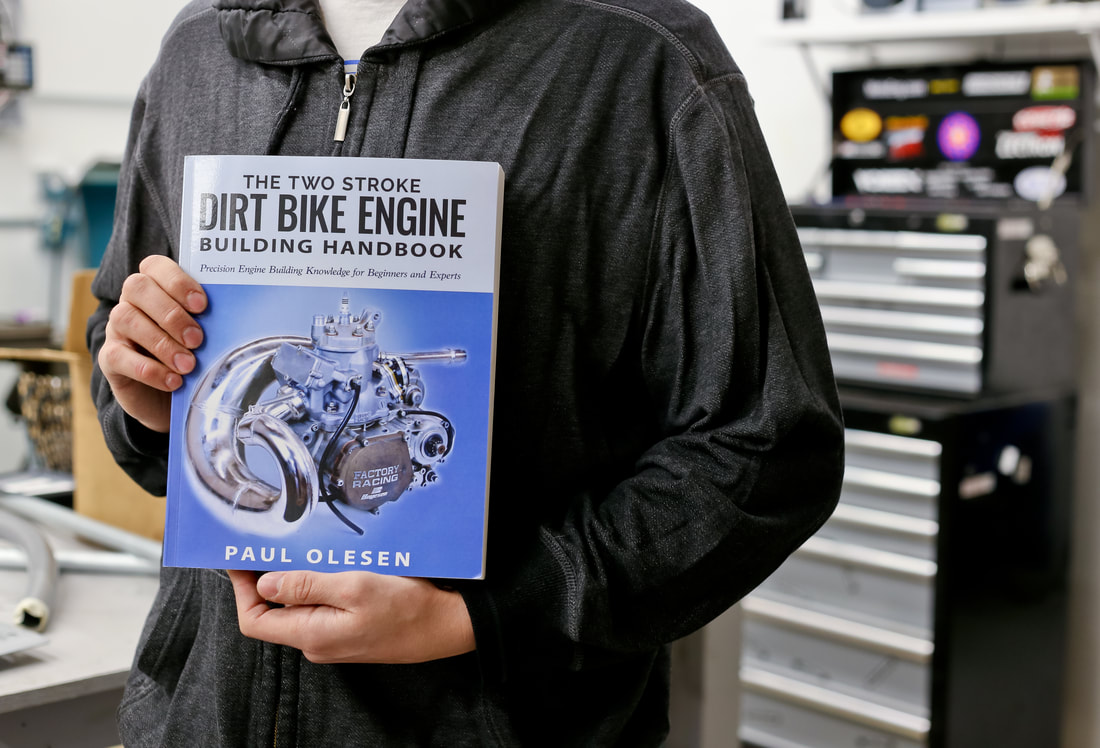

Simply follow this link to grab your copy: The Two Stroke Dirt Bike Engine Building Handbook

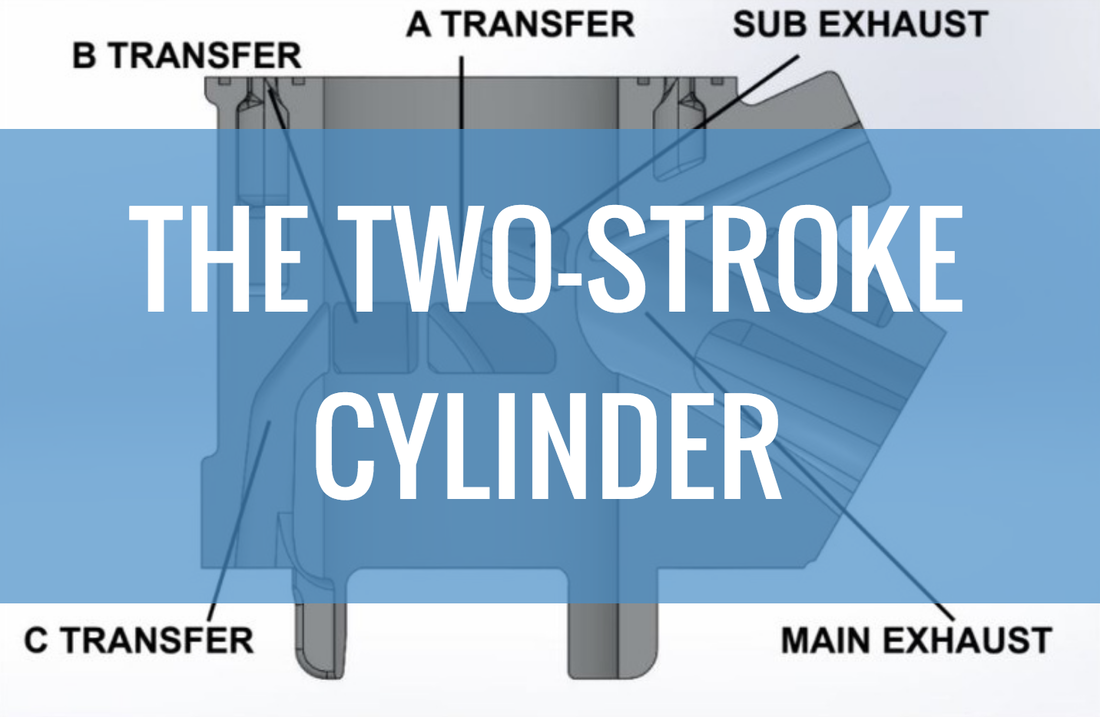

| I want to thank you all for your support and patience as we've worked to finish up the two-stroke book. When I started working on the book shortly after launching the four-stroke book I never imaged it would take as long as it did! The two-stroke cycle is my favorite type of internal combustion process and I'm thrilled to share my knowledge on how to correctly build two-stroke dirt bike engines. As an engineer I've always been fascinated with ways in which designs can achieve a lot in terms of function while remaining simple in execution. The two-stroke engine exemplifies this by capturing a complex gas exchange process in a handful of moving parts. |

I used three different engines to ensure all the common design variants across manufactures were captured so that the reader will not have a problem tackling any engine build they encounter.

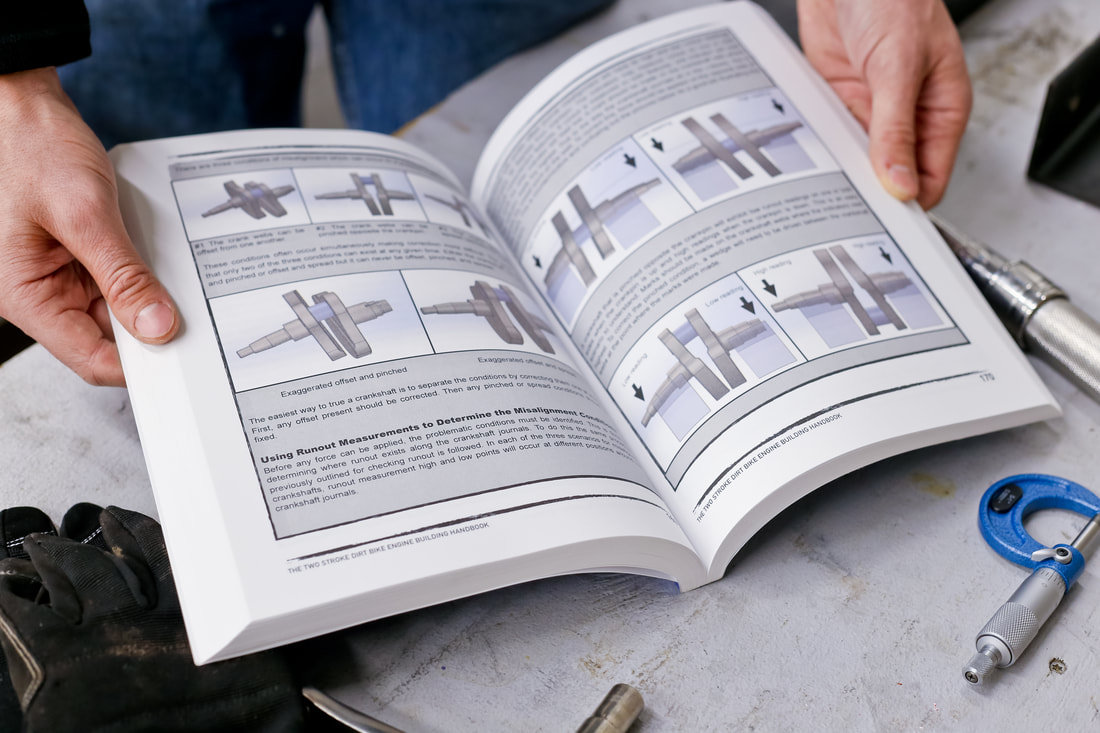

I've also gone far beyond just capturing the rebuild process and have included chapters on important topics that must be understood in order to correctly diagnose problems, inspect parts, and reassemble the engine. Within the book you'll find info on tests used to diagnose problems, a discussion on premature wear, and a thorough how-to on using all the precision measurement tools necessary for correctly inspecting components.

| While service manuals tell you when to do things, I've detailed the how and why behind the entire process of what you are doing. My goal with this book is to increase your engine building knowledge, make you a better engine builder, and explain why it's important to execute each step in a precise and predictable way. As someone who loves tinkering and making engines perform better than stock, I included sections on performance/race engine building techniques, which cover checking/setting port timing, checking squish clearance, and checking compression ratio. |

Thanks again for all your support as we've grown DIY Moto Fix from an idea to a thriving community of riders who are passionate about making their machines perform better through their own hard work.

-Paul