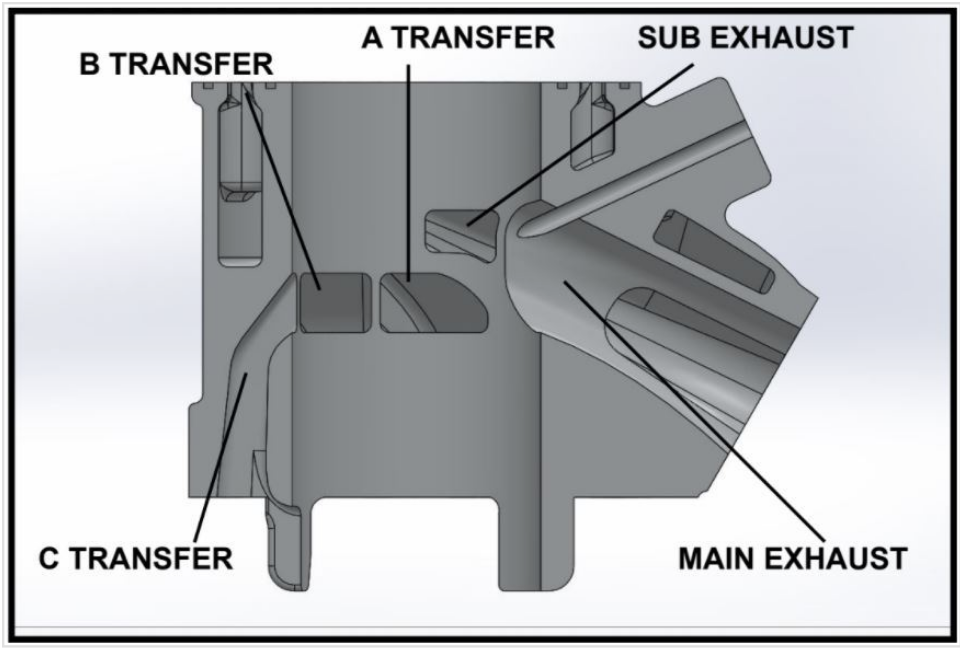

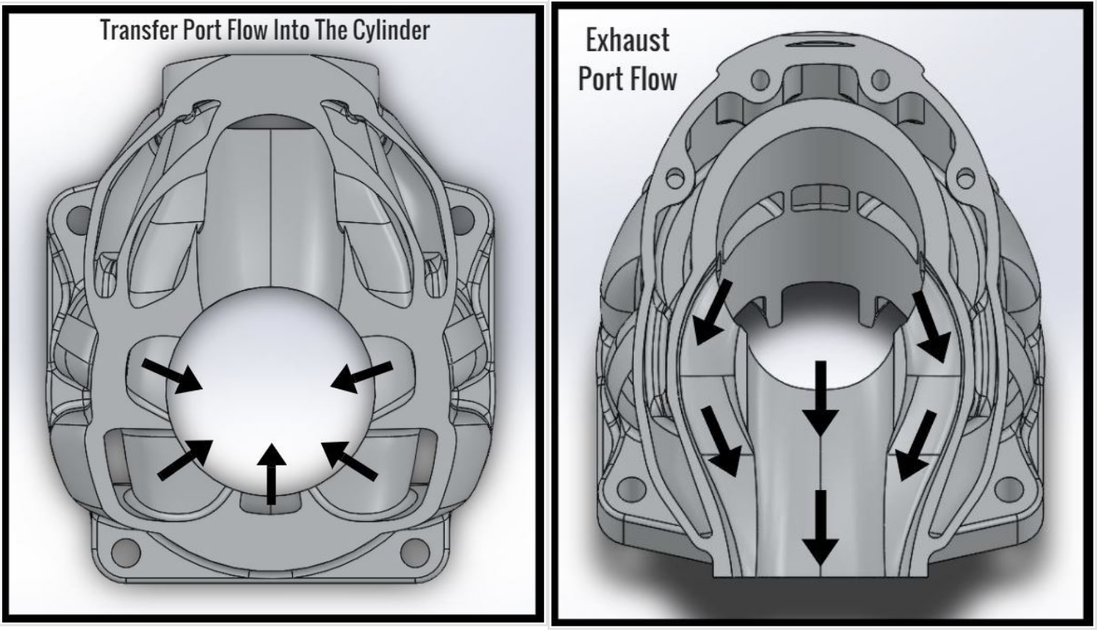

The transfer ports are responsible for moving fresh air and fuel up from the crankcase into the cylinder. This occurs as the piston travels downward after the cylinder has fired. Once the piston uncovers the tops of the transfer ports the blowdown phase is complete, at which point much of the exhaust gas has been expelled from the cylinder. As the transfer ports begin to open, the exhaust pipe sucks fresh mixture up through the transfer ports into the cylinder. To a lesser extent, the downward motion of the piston also aids in creating a pressure differential between the crankcase and cylinder. The shapes and flow capabilities of the transfer ports play a big part in how effectively the cylinder can be scavenged of exhaust gases and filled with fresh air and fuel. The transfer ports also help cool the piston.

General insights into a cylinder’s performance can be made by characterizing attributes such as the timing of the exhaust and transfer ports, the port widths, and the directional flow angles, but a deeper analysis is required to truly optimize a cylinder. Today, tuners and designers rely on computer software which computes a port’s specific time area (STA). As defined in the EngMod 2T software suite, “STA provides an indication of the effective port window area that has to be open for a certain length of time to allow enough gas to flow through the port to achieve the target power at the target RPM for the given engine capacity”. STA values are used to quantify the exhaust, transfer, and inlet port geometry as well as the blowdown phase of the two-stroke cycle. The blowdown phase occurs between exhaust port opening and transfer port opening and is one of the most important parameters in predicting engine performance.

By manipulating STA values and subsequently the height, shape, and size of the exhaust, transfer, and intake ports, an engine’s power characteristics can drastically be altered. Port modifications can be made which allow more air to move through the cylinder, ultimately increasing the power of the engine. Conversely, ports can be filled or welded and reshaped which tame the engine and provide less peak power but a broader spread of power. Simple modifications to the ports can also be carried out which improves the air or exhaust gas flow through the port yielding better cylinder scavenging.

Can I modify my own cylinder?

Who should consider two-stroke porting modifications?

- Major port modifications would include tasks such as significantly changing the port timings (by either removing or adding material), altering the shapes of the ports, or changing the directions the ports flow. Anyone drastically altering their engine, such as turning an MX engine into a road racing engine, should consider major porting modifications. Other examples of applications that may require or benefit from major port modifications include drag racing, hare scrambles, ice racing, or desert racing.

- Minor port modifications would include basic tasks such as removing casting flash, slightly altering the ports to achieve the stock port timing, and correcting areas that result in minor flow deficiencies. Just about everyone could benefit from these types of corrective actions; however, if the engine is already performing or producing adequate power, they often aren't considered.

| I hope you enjoyed this writeup on key features affecting the performance of two-stroke cylinders. If you are on the prowl for more information on two strokes, specifically how to rebuild your two stroke dirt bike engine, you can check out our book on engine rebuilding by clicking below. Thanks for reading and have a great rest of your week! -Paul |