In this write up I’ll cover how to remove a broken bolt using a screw extractor. Screw extractors can be found at most hardware stores, come in a variety of sizes, and are cheap. More elaborate extractors can be found through sites such as McMaster-Carr which may or may not work better for your given application.

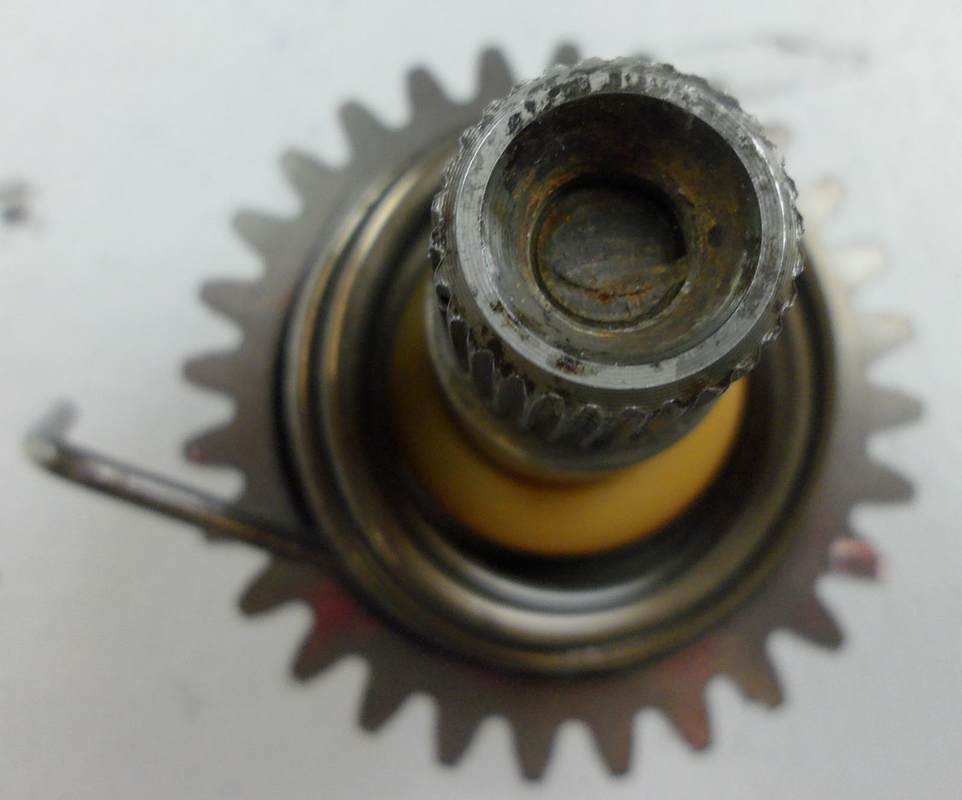

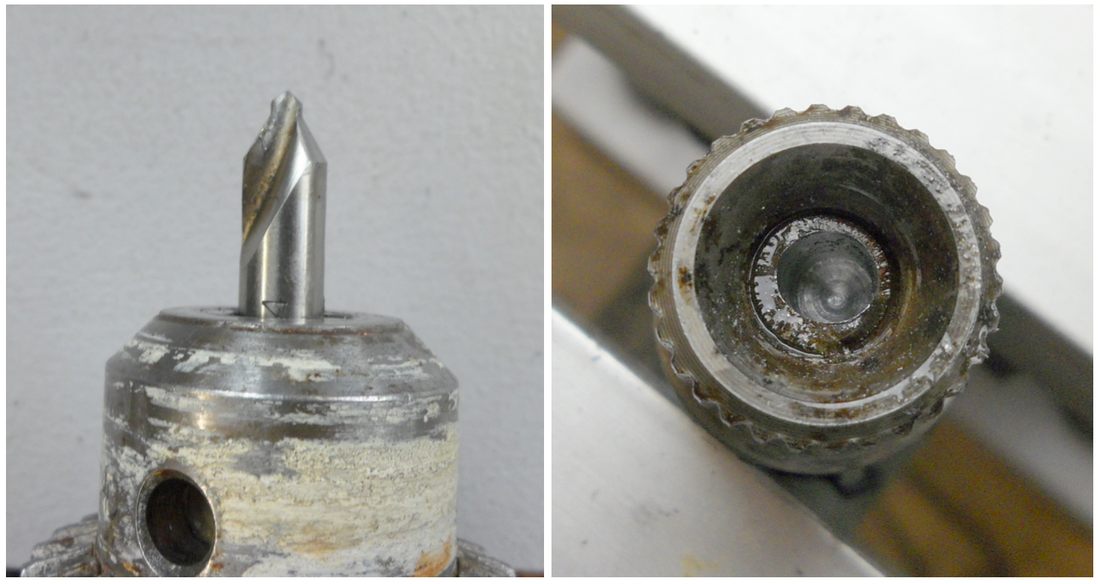

It would be far too easy for a bolt to break evenly and flat. Instead, an uneven breakage point is characteristic of a broken bolt. Depending on the severity of the unevenness of the broken face, it can be next to impossible to get a drill bit to track true, even with a punch mark to get started on the right track. To help the drill bit center itself and to locate it so that it drills in the center of the bolt I like to use a rotary burr or a grinding stone to create a smooth and shallow impression.

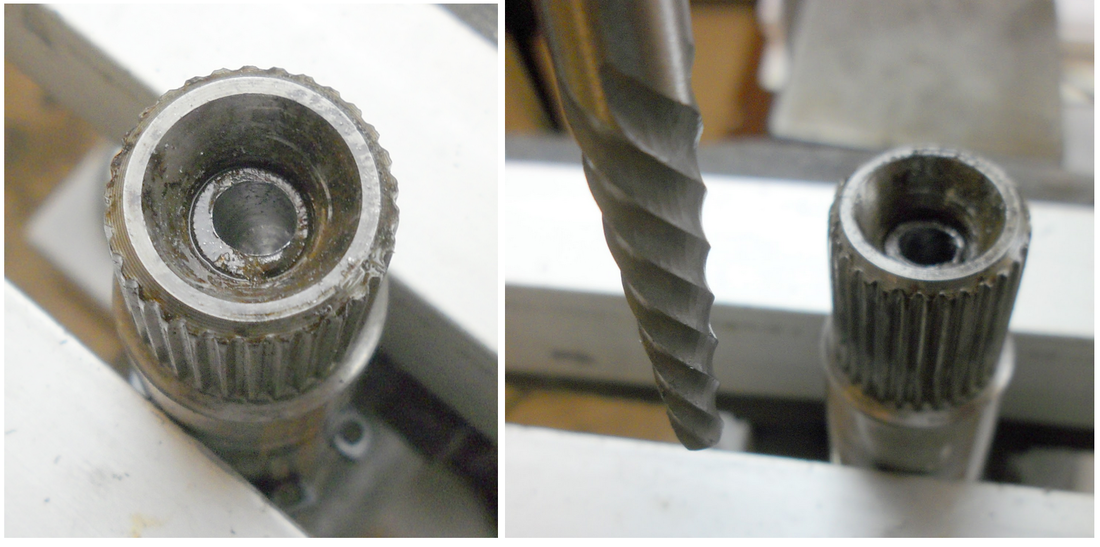

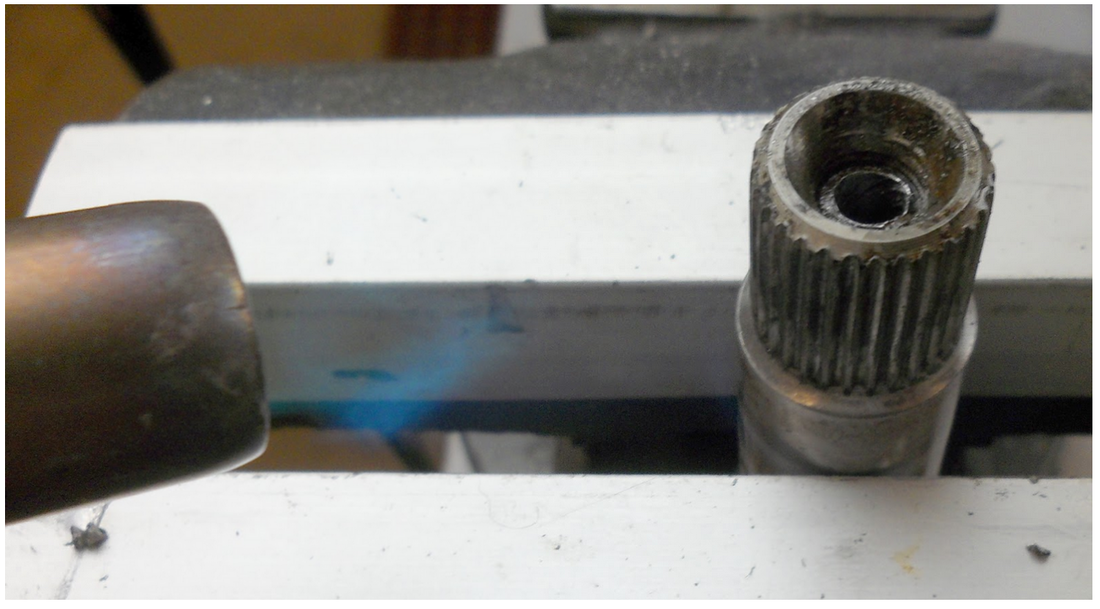

Once the hole is deep enough the extractor can be fit into the hole and slowly turned to get a feel for how stuck the bolt is. The bolt may or may not turn depending on how stuck it is. The worst thing that can happen is the extractor is turned too hard causing it to break off inside the stuck bolt. This makes things even more complicated and should be avoided at all costs. If the bolt doesn’t turn right away with moderate force, don’t push the issue. Instead, use a torch to heat the end of the shaft surrounding the bolt threads.

If you enjoyed this post and want more weekly updates on dirt bike maintenance and technical tips, subscribe by entering your email below.

Sign me up for the eNewsletter!

I'm ready to take my dirt bike knowledge to the next level.