Performing a leak down test is the best method for determining if and where air leaks are coming from. A leak down test is fairly simple to perform and can provide tremendous amounts of information about the health of an engine. I typically like to perform a leak down test on an engine if I’m having trouble jetting the engine consistently, if I’ve bought a used bike with a suspect past history, or when I’m finishing up assembling a new engine. The biggest mistake I see a lot of people make is when they rebuild an engine with new parts and skip the leak down test. I cannot count the number of times where I have rebuilt an engine with new parts and then performed a leak down test to find a gasket that was not sealing properly or another part that was causing a problem. The leak down test is imperative and ultimately becomes a form of cheap insurance against the time and money that has gone into the build...

Although performing the leak down test is fairly simple, setting it up may be a little more difficult. I often find I need to make special adapters and block off plates dependent on each engine. If you have a reed valve engine, I like to install the reed valve and intake manifold. Then I make a plug which is the size of the carb/throttle body OD on the intake manifold side and slide that homemade plug into the intake manifold boot. Depending on your exhaust manifold there are two options for blocking off the manifold. First, it may be possible to find a rubber plug to plug-up the manifold directly. Most of these rubber plugs will be the expandable type and can sometimes be found at building supply stores like the Home Depot. Second, use the manifold as a template to make a plate, which then you can bolt in the manifold’s place. A steady helping of grease can be used to seal the block off plate to the cylinder.

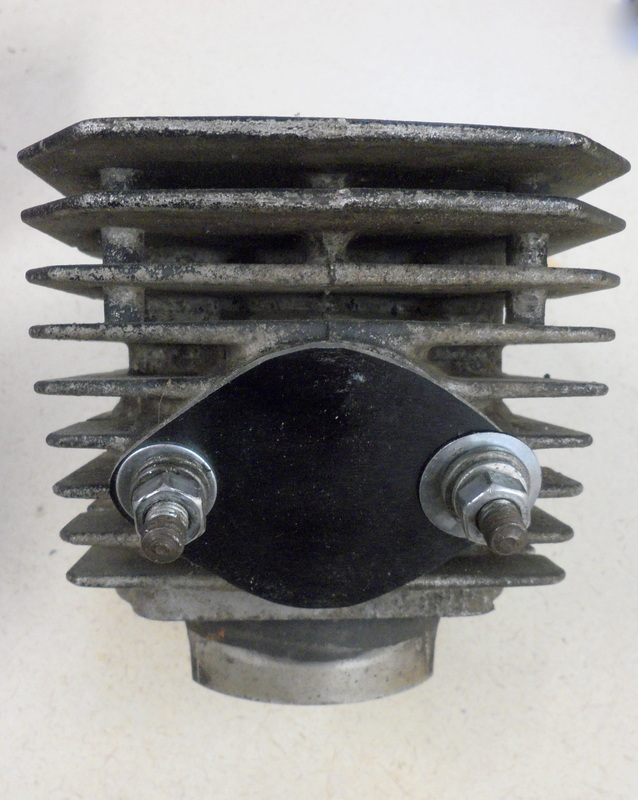

Pictured below is how I like to make my intake manifold plugs. I use a simple schrader valve and tap a fitting into the plug to accept the pressure/vacuum gauge.

Once your setup is complete, pressurize the cavity to 5psi and start timing. If the pressure is lost quickly there is a large leak in the system and now you need to find it. I like to use a squirt bottle with soapy water to hunt for air leaks. It is also possible to hear the audible hissing sound from the leaks, which will point you in the right direction. Once you identify a leak you will have to determine what is causing it and remedy that problem before trying the leak down test again. This part of the process can be frustrating and time consuming, but it is definitely worthwhile. Be sure to spray your block off plate and manifold plug you made for leaks, sometimes these homemade parts can be part of the problem.

If you’re able to hold 5psi for 5 minutes you’re golden. Sometimes this standard is not always achievable, and when that happens I am comfortable settling for a 1 psi drop over five minutes. Even with brand new parts I am not always able to maintain 5psi and believe this is due to parasitic leakage past some of the seals or gaskets. In my opinion, anything more than a 1psi drop means you should still be chasing that leak.

I want to make a point of passing on some additional info I have heard over the years for the sake of completeness of this article. Other builders I have worked with will recommend testing vacuum for five minutes at 10in Hg (equivalent to 5psi of pressure) as well which will test the seals under vacuum. I have yet to find a seal that has passed under pressure but not under vacuum so I wouldn’t fret too much if you don’t have a means to pull vacuum when testing. If anyone out there has encountered this scenario I would appreciate your input.

Good luck with your leak testing and I hope you find this article useful! Feel free to post any questions or comments you may have. There are numerous methods out there, however this method is what I use and have had the best luck with.

Moto Mind - Empowering and Educating Riders from Garage to Trail

Be sure to sign up to my E-newsletter for more awesome tech tips, maintenance advice, and repair procedures! Just click the button below.

Sign me up for the eNewsletter!

I'm ready to take my dirt bike knowledge to the next level.