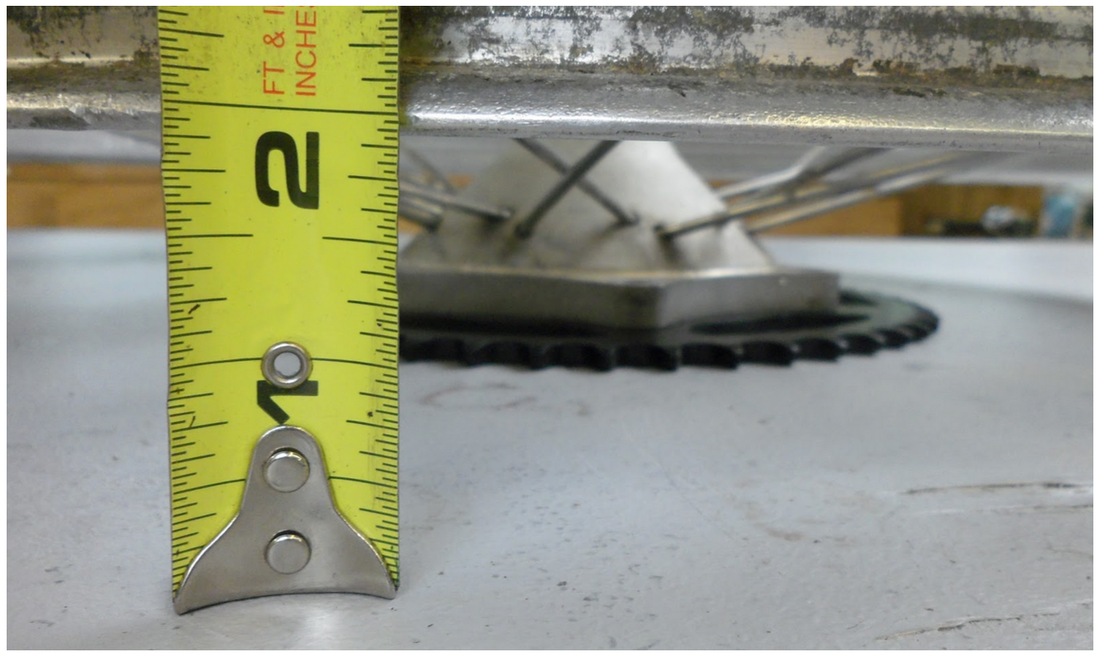

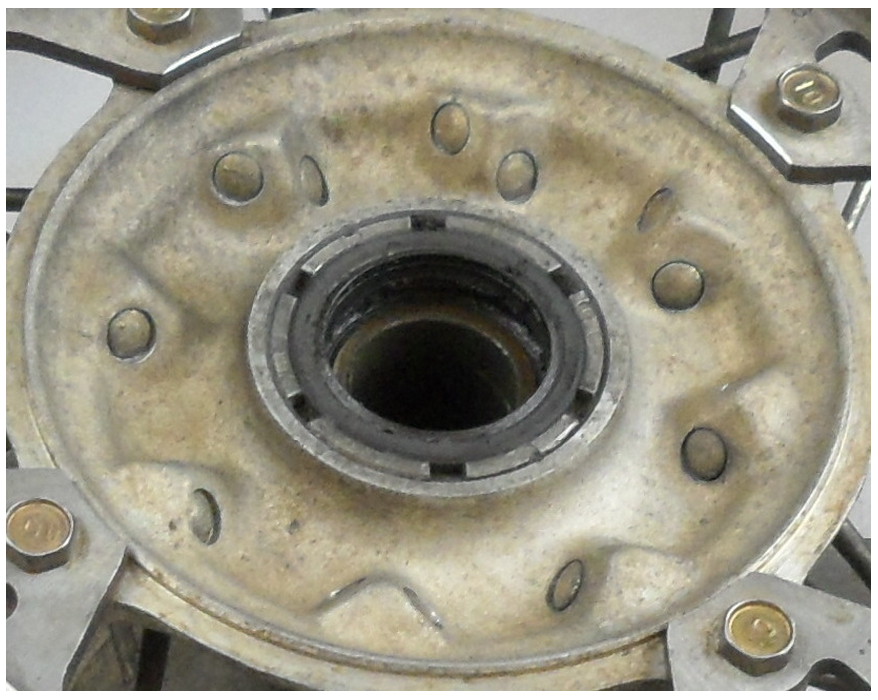

As you can see I have a great example of a wheel assembly that is way past its prime. The spokes are bent, loose, and the nipples are mostly all stuck. On top of that, the rim is cracked in a couple spots necessitating further repairs.

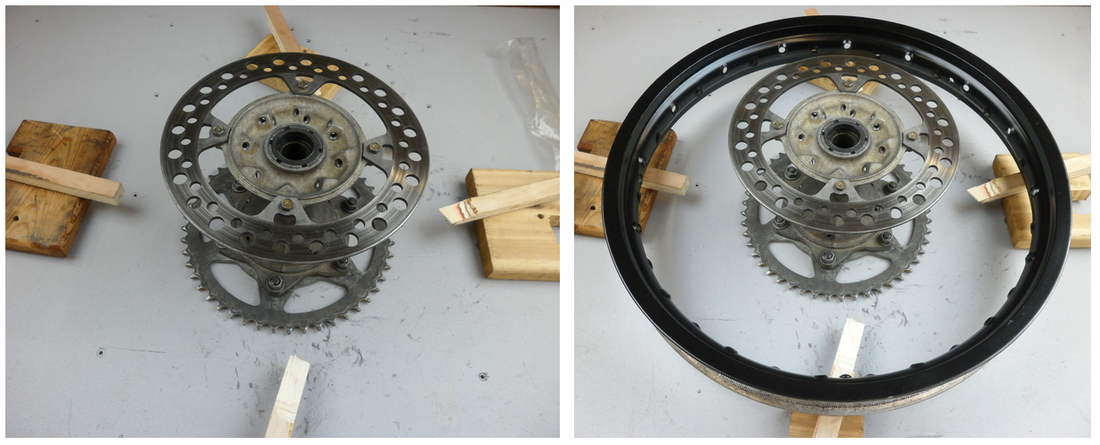

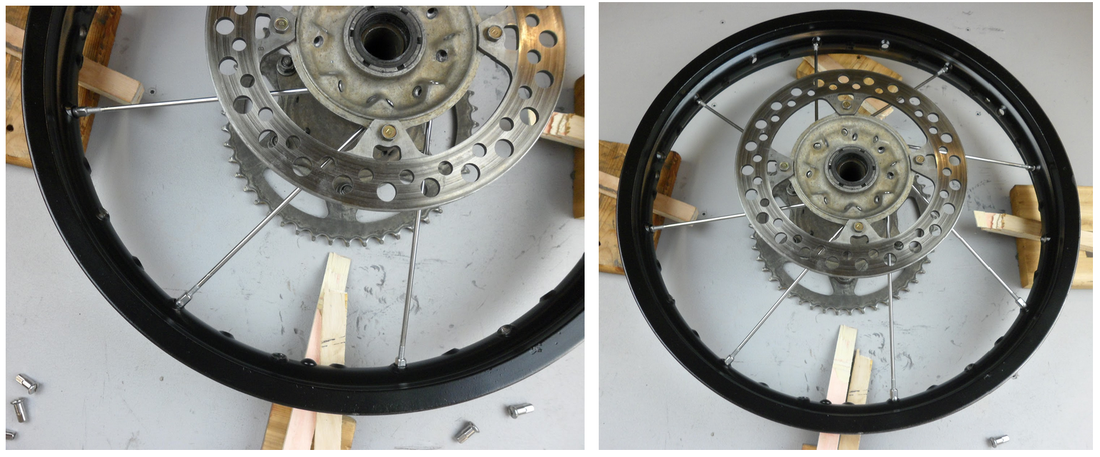

Once all the outside spokes have been laced in one side, lace all the inside spokes on that side. Don’t be afraid to pull the rim a little bit from side to side to help generate enough clearance so that the end of the spoke can easily pass through the hole in the rim. The rim may also have to be moved up and down a little bit to help center the spoke.

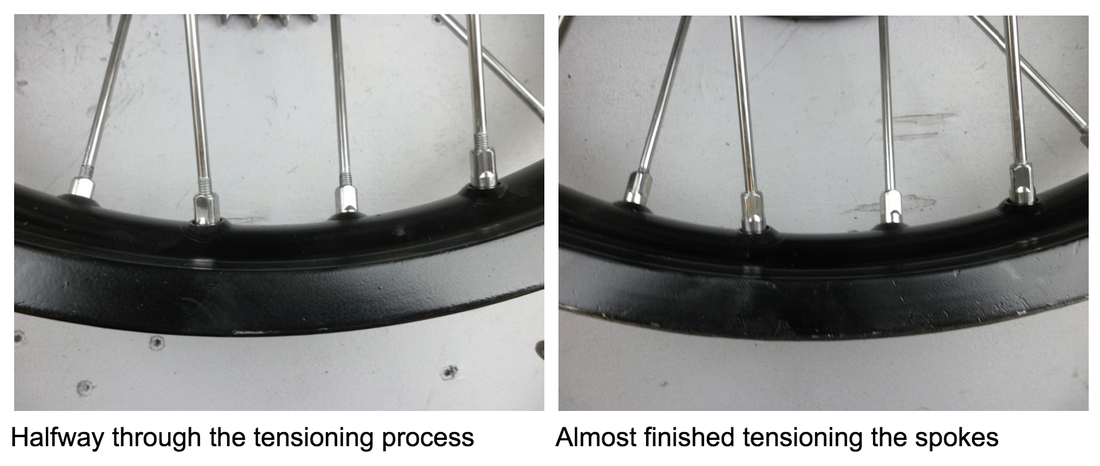

Another sign that the job has been done properly is that the spokes will not pass through the ends of the nipples.

If you found this post beneficial and enjoy tackling projects yourself, you may find my eBook, The Four Stroke Dirt Bike Engine Building Handbook a great read. The book is packed full of in-depth precision engine building knowledge, a detailed overview of performance part selection, and many photographic examples which outline what to look for in problematic parts during a build. The eBook comes in PDF format, is sent immediately to your email inbox, where you can read it or print it off and bring it into your workshop. Right now we have an awesome deal running where all website visitors get 20% off when they enter the discount code fixityourself2015 before purchasing. To learn more about the book, check out the Table of Contents, and read some testimonials, click here.

Do you have any helpful tips you want to add? Please leave a comment below and share your experiences! If you loved this post, feel free to sign up for my eNewsletter where I'll send weekly dirt bike maintenance tips and tricks right to your email inbox.

Sign me up for the eNewsletter!

I'm ready to take my dirt bike knowledge to the next level.