Preparation

From a tools standpoint, a crankcase splitter tool is a worthy investment because it will help ensure the job goes smoothly. Case splitters are relatively inexpensive and widely available. Alternatively, for the budget conscious or lesser prepared, a case splitter is something that could be fabricated. Whether buying or making, ensure you pick up a model with a protective end cap for the crankshaft or fabricate one. We’ll discuss the end cap later. The other tools required are all fairly standard and include your typical sockets, wrenches, and soft mallets.

Tips + Techniques

After the crankcase bolts have been removed, the crankcases should be inspected one final time to ensure no hardware that should have been removed prior is hitchhiking. Trust me, trying to separate cases only to find there is one last forgotten bolt is quite frustrating! Once you’re confident all the necessary hardware has been removed, position the cases on the blocks with the correct half facing up.

Next, install the protective cap over the crankshaft. I advise using the cap whether you own a two or four-stroke simply because in both cases it helps preserve the end of the crankshaft. This is of particular importance on four-stroke engines that utilize an oil feed that passes through the crank.

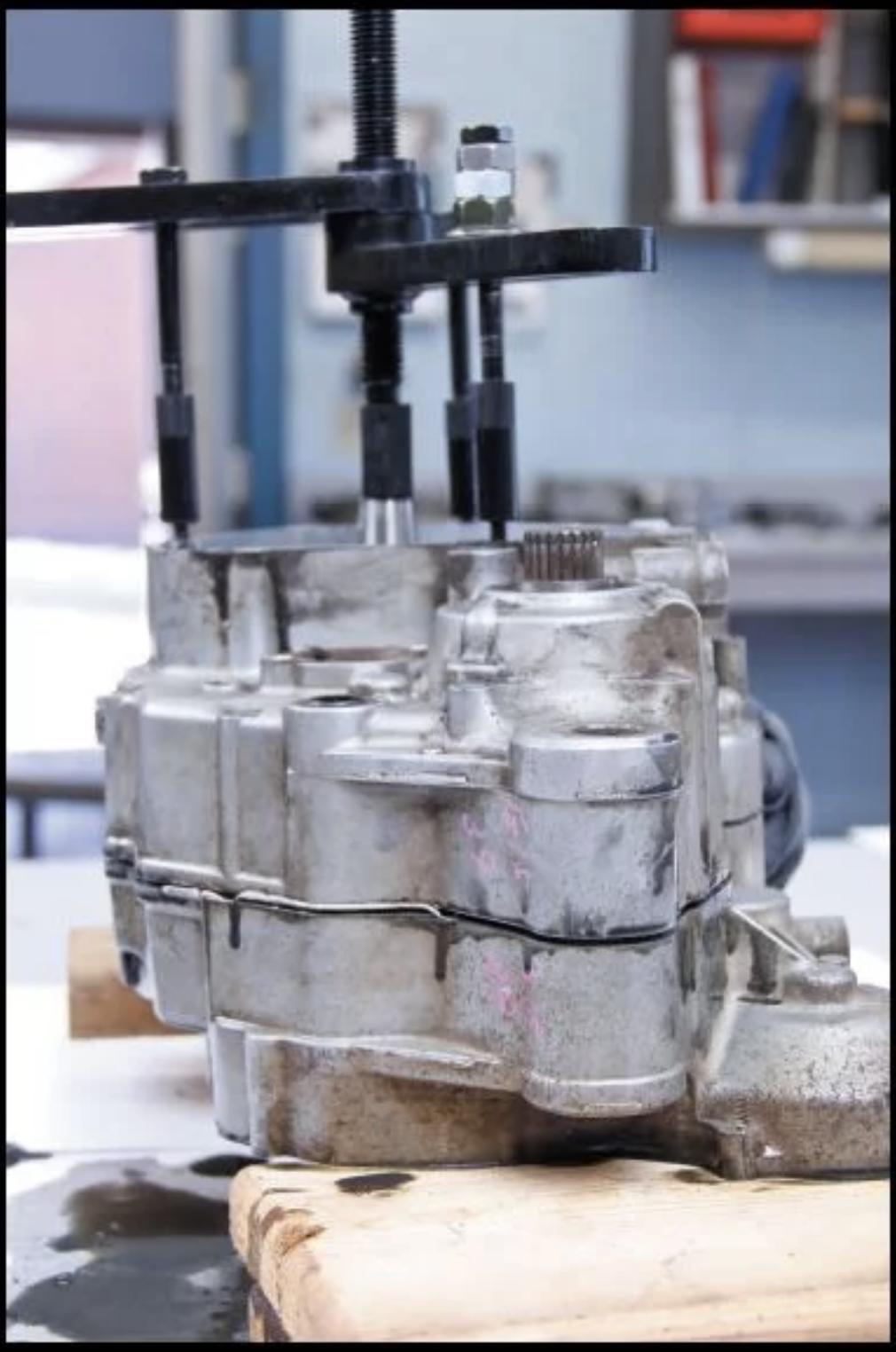

With the crankcase splitter installed begin tensioning the main bolt against the end of the protective cap. Proceed to tighten the bolt until the crankcases begin to separate about a 1/16” (1.5mm). Once separation has occurred, make sure that separation is even all the way around the cases. Due to the way the case splitter loads the cases, the area near the output sprocket tends to lag. Case separation needs to be even so that the dowel pins used to pair the cases together don’t bind.

What I’ve described is the ideal sequence of events for a successful case separation, however, occasionally the cases won’t be as cooperative. In the past, I’ve had to deal with crankcases where moisture has found its way into the dowel pin bores and corroded the dowel pins. This effectively seizes the dowel pins in their bores and makes the separation job more challenging.

If the crankcases are being resilient to separation, stuck dowel pins may be a potential problem. Most dowel pins are located opposite one another and their exact position can often be referenced in the service manual or in the crankcase section of part microfiches. Once the location of the dowel pins has been confirmed, a torch can be used to lightly heat the dowel pin areas. Heat will expand the metal surrounding the dowel pin and aid in freeing up the stuck pin bore. Usually, a few careful rounds of heat, tension on the splitter, and well-placed tapping is enough to free up the pesky cases and get them separated.

Alternatively, if the heat does not help, applying a penetrant to the pin bore areas is another option that may help free things up. If you find yourself dealing with stuck cases, the key is to be patient and think through all your options. In these types of situations, most mistakes are avoidable and are usually the result of rushed decisions.

Once the cases have been separated, the remaining tasks of removing the gearbox and pushing the crank out of the remaining case half can commence. I hope you’ve enjoyed this write up on crankcase separation and that it makes you more prepared for the job. If you’ve got additional crankcase separation tips that you want to share, please leave a comment below.

For additional engine building information, whether two or four-stroke, check out my engine building handbooks. Each handbook is offered in print or digital form, contains over 250 color pictures, detailed instruction from start to finish on full rebuilds, and contains a wealth of information pertaining to diagnostic testing and precision measuring.

Sign me up for the eNewsletter!

The DIY Moto Fix Weekly eNewsletter is full of in-depth technical and maintenance tips to help you care for your dirt bike.