My powersports story started at a young age, however, thanks to parental restrictions I was never able to own a bike until I was 18. Once 18 hit, I promptly bought a 1984 Honda Nighthawk 700 from my high school. The bike had been donated by a member of the local community and I had my eye on it for years as I watched students try unsuccessfully to make it run right. Thanks to my never-ending curiosity, that bike very quickly got rebuilt. To the dismay of my parents, it got ridden a hell of a lot.

Shortly thereafter I graduated high school and then attended the University of Minnesota, where I was slated to follow in my father’s footsteps and become a dentist. I don’t recall too many times where I had actually thought that this career path was going to become a reality, so naturally my interest in higher education dwindled at an alarming rate.

Simultaneously my interest in motorcycles was at an all time high. I was fascinated by the old Kawasaki two-stroke triples. I had never before seen a two-stroke in a motorcycle and their simplicity, light weight, and abundance of power drew me to them. In a twist of Craigslist-fate a deal for a pair of 1975 Kawasaki H2s popped up in Dallas. Before I could fully rationalize the consequences of skipping an exam, I was on my way with a friend to pick these basket cases up.

On my way down to Dallas it hit me that without knowing what I wanted to do with my life, continuing going to school was pointless. I promptly quit two years into my college education, yet again much to my parents’ dismay. I had always made money running a painting business in the summer, so I did that for awhile to make ends meet. While painting has never been a glamorous business, it was quite profitable and an important part of my life as it taught me the basics of running a business, allowed me the freedom to set my own schedule, and I learned how to deal with and manage people.

Somehow I convinced my parents that going to Wales and attending The University of Wales was a good idea, I applied, and got accepted shortly after. Finally I was going to go learn about something I actually wanted to, travel the world, and get a degree in motorcycle engineering. The move to Wales was exhilarating and things really started to take off for me once I began my studies. The structure of the program, the way in which the coursework was carried out, and class sizes were all a lot different than I had expected- but in a good way.

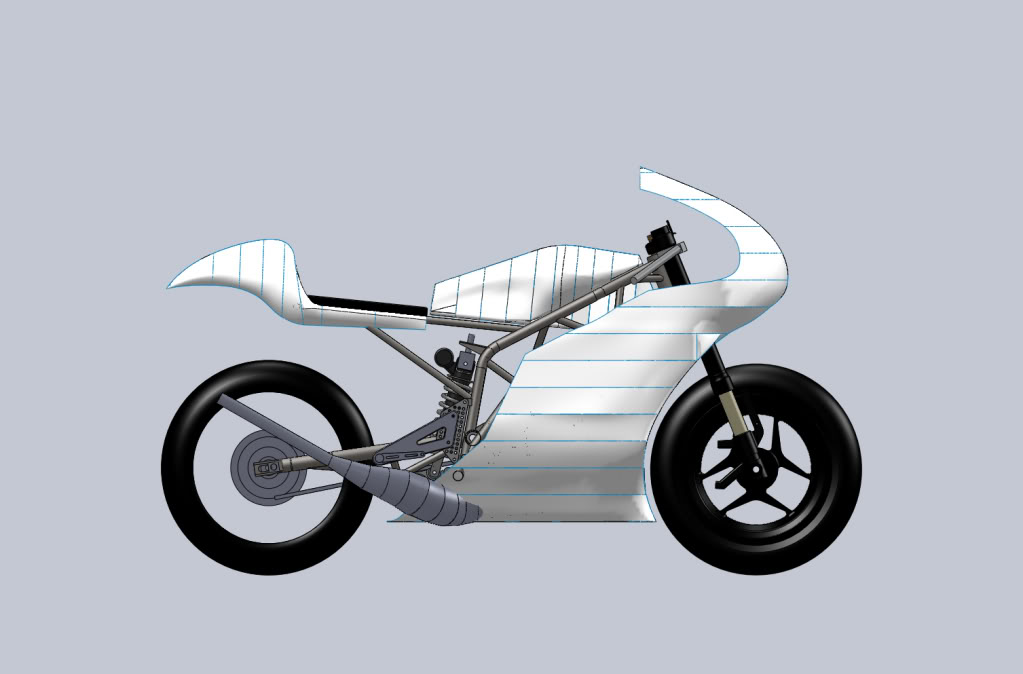

The first year was a cakewalk, but it allowed me ample time to learn CAD programs, design a couple fictitious bikes, make friends, and enjoy the Welsh countryside. Towards the end of the year I decided I would design and build my own motorcycle, which I would then intend on racing in the Central Road Racing Association’s club racing events at Brainerd International Raceway in Minnesota. To keep costs down and the project manageable, I decided to build a super mono powered by a Kawasaki KX500 two stroke engine.

After befriending some locals who were enthused about my ambitious project as I was, in one fell swoop I procured the rights to use all the equipment I required at the odd hours I was intending on working on this bike. It was as if the universe had aligned for the things I had wanted all along as soon as I started asking for them. Quickly I got the jigs made for the frame and swingarm, enlisted the help of my father to work on the fiberglass components, and devised a plan to try and extract more power out of the engine.

The biggest hold up that summer was having to teach myself how to weld. That exercise took roughly a month of practice on thin walled tubing and a hefty sized chunk of my own melted skin before I felt proficient to proceed to tackle a real frame. Fortunately, or unfortunately depending on how you look at it, I cocked up the frame design by trusting a friend’s engine model. My first go around at a frame didn’t end up fitting anything, but I got plenty of extra welding practice! By the end of summer the bike was 85 percent complete and I was able to finish the rest of it up over the Christmas and Easter breaks.

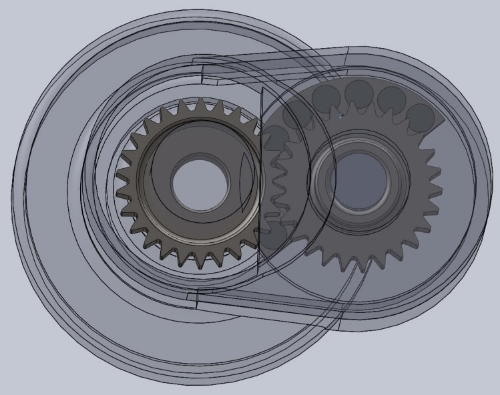

Much to my dismay, simply changing the balance of the crankshaft did not in fact move the vibration to a more tolerable direction. I needed another solution. After much problem solving, I decided to try and graft on a counter balance assembly I designed to cancel out some of the forces that lead to engine vibration. This proved to be a difficult task with my amateur machining skills, but through much trial and error I managed and the balancer worked!

Once work was finished for the day, more often than not I went over to my boss' house. He had a decent size shop with a dyno, a hefty amount of tools, and the usual machining equipment- all the things I was requiring to make my world go round. Towards the end of my second year of school I had designed a fuel injection system which I was adamant about implementing onto my bike. That whole summer I spent my time incorporating the system into the engine and learned how to tune the engine on the dyno. By the end of summer my bike was ridable, and I was spending more and more time out on the road test riding. I had hoped to take it to the track for the final race of the year, but other engine problems cropped up and I, along with the bike, ended up staying home.

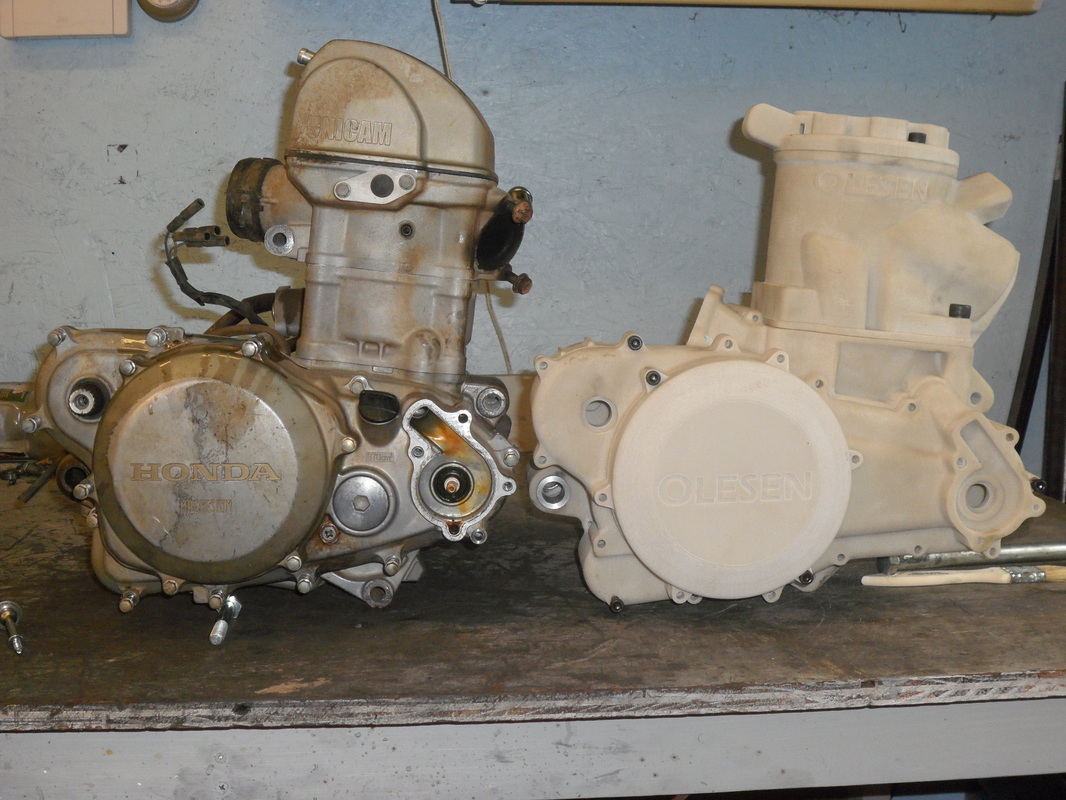

Due to the fact that we actually had a couple Honda CRF450 bikes in the school’s workshop, and parts were cheap and cheerful, I decided to use the gearbox along with a few other parts from that engine. The rest of the engine I designed from the ground up. By the end of my third year I was calling my friends at S & S to help me out with some 3D printing so I could test fit the engine into my frame and the CRF frame. As most students nearing graduation, I was nearing the time where I needed a job, and I didn’t have any spare money to spend on having parts made so the 400cc single project had to be put on hold.

One of the places I toured that piqued my curiosity the most was Mercedes AMG in the United Kingdom where the Mercedes Formula I engines are designed. I ended up going there twice for interviews and getting a job offer to work there, but thanks to work visa restrictions I was never able to secure the offer since the regulations tightened up after 2012.

At that point there was really only one company in America where I thought my skill set and personality would be a good match, and that was at Erik Buell Racing. I had applied at the company in the fall of my final year and finally after four months of patiently waiting, I had heard something. An interview was arranged so I came home, loaded up my bike and prototype engine in the back of my van, and set out to East Troy. At the end of the day, after all their questions were answered, it was quite satisfying rolling out my hand built race bike in the sportbike company’s parking lot to show all the interviewing staff what I had done. The interview staff had never had another candidate who built and brought a rolling resume before and they were thoroughly impressed. Right then I realized my persistence at building my own bike had paid off and was largely responsible for landing me two jobs a lot of people only dream of. I was brought on as a powertrain engineer in the fall of 2013 and spent a year in total working for them before I started DIY Moto Fix.

So why start DIY Moto Fix? Well, I've got one heck of a blog post for you on that. Click that link to read on as to what inspired me to get this business off the ground.

Throughout my career I have continued to meet wonderful people, learn new things, and further my knowledge of two wheeled vehicles. I hope in a small way my exploits, triumphs, and failures will all be valuable lessons.

Be sure to sign up to my E-newsletter for great tips on repairing and maintaining your bike! Click the button below to sign up!

Sign me up for the eNewsletter!

I'm ready to take my dirt bike knowledge to the next level.