| Hey everyone, I want to introduce an article I wrote in collaboration with Wiseco where I discuss piston wear and replacement. I think you'll find it useful because it will give you an idea when pistons should be replaced and how they wear. Check it out below! The piston in an internal combustion engine is arguably one of the most important components found in the engine. When it comes to high-performance engines used in powersports applications it is also a component that is regularly replaced and serviced. Knowing when your piston should be replaced and how it wears is key to maintaining a reliable engine. In this article we’re going to discuss replacement intervals, piston wear, why it’s important to replace the piston, and piston replacement options. |

Piston wear will typically occur in four key areas for both two and four-stroke engines which include the piston skirt, wrist pin bore, ring grooves, and piston crown. The next time you disassemble your top end keep an eye out for these wear points.

Piston Skirt Wear - The piston skirt is the portion of the piston that gives it its cylindrical shape. Nowadays on four-stroke engines, the piston skirt is very short and limited to the major and minor thrust faces of the piston. For reference, the thrust faces typically correspond with the intake and exhaust valve sides of the cylinder head. Two-stroke pistons use the same nomenclature but feature much longer more pronounced skirts.

Piston skirt wear occurs because of the thrust loading that results from the inherent geometry of the crank mechanism as the engine fires. Peak combustion pressure occurs slightly after top dead center which causes the piston to thrust into the cylinder wall.

On two-stroke engines, skirt wear can occasionally be heard audibly while the engine is running which is commonly known as “piston slap”. A rhythmic metallic sound often accompanies a loose or worn piston when the engine idles. What can be heard is the piston rocking back and forth in its bore as it reciprocates.

Piston Crown - Piston crown wear will occur as a result of aggressive or improper tuning and on four-stroke engines a damaged or mis-timed valvetrain. Engines operated with a lean mixture at full throttle will see abnormally high combustion temps which can cause detonation. The results of detonation will be visible on the piston crown as a pitted or eroded surface.

Ring Groove Wear - The piston rings move in and out of their grooves as a result of the ignition of the air/fuel mixture in the combustion chamber. Once the mixture is ignited the cylinder pressure increases which energizes the compression ring and forces it against the cylinder wall causing it to slide in its groove.

Ring and groove wear can occur due to the sliding and reciprocating motion of the rings and can be exasperated by carbon deposits that accumulate in the ring groove. Ring and groove wear can be qualified by thoroughly cleaning the ring and groove and then measuring each. Most service manuals outline specifications for ring width, groove width, and piston ring to ring groove clearance.

Wrist Pin Bore Wear - Wrist pin bore wear occurs as a result of the loading of the wrist pin joint through inertia and combustion loading. As a result, the wrist pin bore will typically wear into an oblong shape. In some engines, wrist pin bore wear will be visible in the top and bottom of the bore. Usually, a portion of the bore will appear burnished or polished. Alternatively, the wrist pin bore can be measured from top to bottom and from side to side. Both measurements can be compared to one another to determine how much the bore has become out of round and to the diameters specified in the service manual.

Between aftermarket suppliers and OEMs replacement piston options are plentiful and can even be overwhelming. The most common upgrade and consideration most riders are faced with is whether or not to move to a forged piston. Forged pistons can be a nice upgrade for many riders because they can offer additional strength and wear resistance over cast pistons.

Forged pistons achieve greater strength than cast pistons through the use of different aluminum alloys and manufacturing processes. The forging process for pistons utilizes a pair of dies that are brought together which puts the aluminum under pressure and forces the material to move in predetermined directions. The forging process results in finished components which have a tighter molecular structure and features optimized for strength. Comparatively, cast pistons are not cast under high pressures and have molecular structures that are not as tight or organized which in severe cases can lead to voids, inclusions, and air pockets.

I hope this article has been helpful in providing an overview of piston replacement intervals, piston wear, and replacement options.

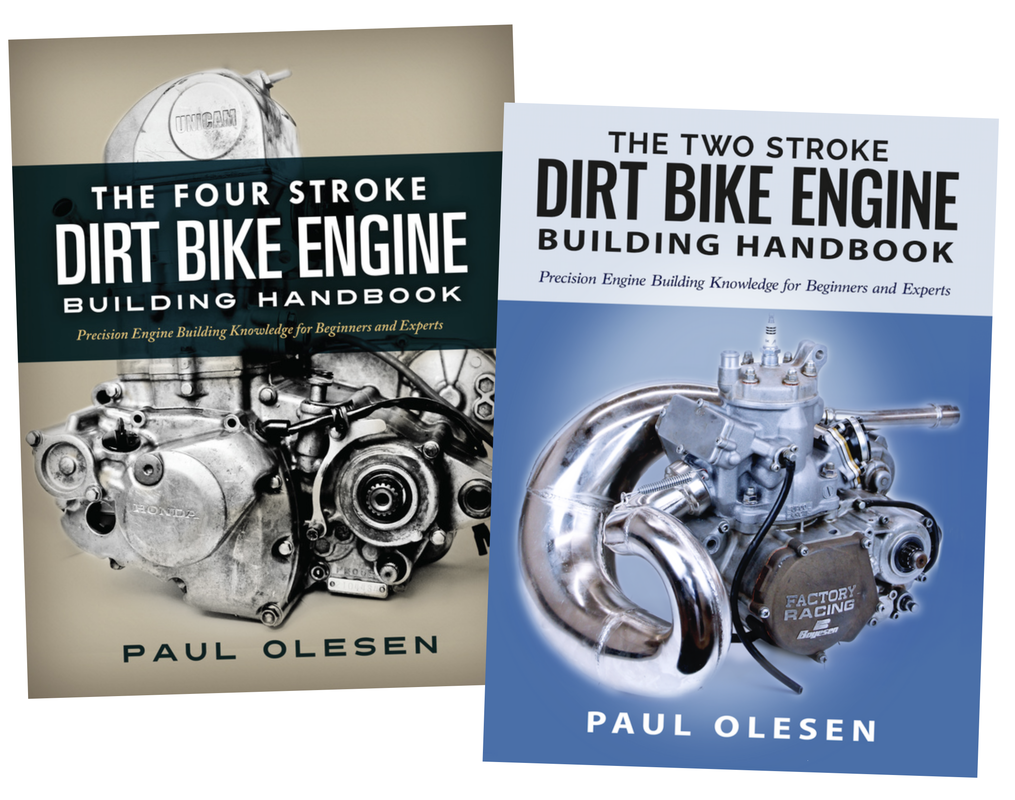

How to Get What You Really Want For Christmas This YearPsst! At DIY Moto Fix we will be celebrating the holidays with our annual four-day sale from Black Friday to Cyber Monday where we discount everything at 20% site-wide. If you want to learn more about engine building and save a little money, this is a great time to pick up a copy of our two and four-stroke dirt bike engine building handbooks. You can learn more about them and the other awesome resources we offer by clicking below. |