I know many of you out there love spending time in your garage or shop and in this post I want to share my plans for my shop. Some of the projects I’ve already tackled, while others will require larger monetary commitments in the future. Hopefully some of the features, projects, and plans I’m thinking about incorporating into my shop will give you some ideas and inspiration of your own.

THE BEFORE

The Planning Stages

- The building was grossly underlit and it was difficult to see what I was doing.

- Energy was being wasted because there was no means to force hot air down once it had risen.

- There was nowhere to store anything.

- The walls, which were covered floor to ceiling in dirty white pegboard, bothered my eyes. Not to mention much of the pegboard had warped due to it getting wet.

- The electric heater was impressive at heating the building up quickly in the event that one forgot to turn the thermostat up for the radiant floor heat.

- The radiant floor heat took 2 to 4 hours to warm the building.

- Windows would have been nice.

- The cabinets were not very durable.

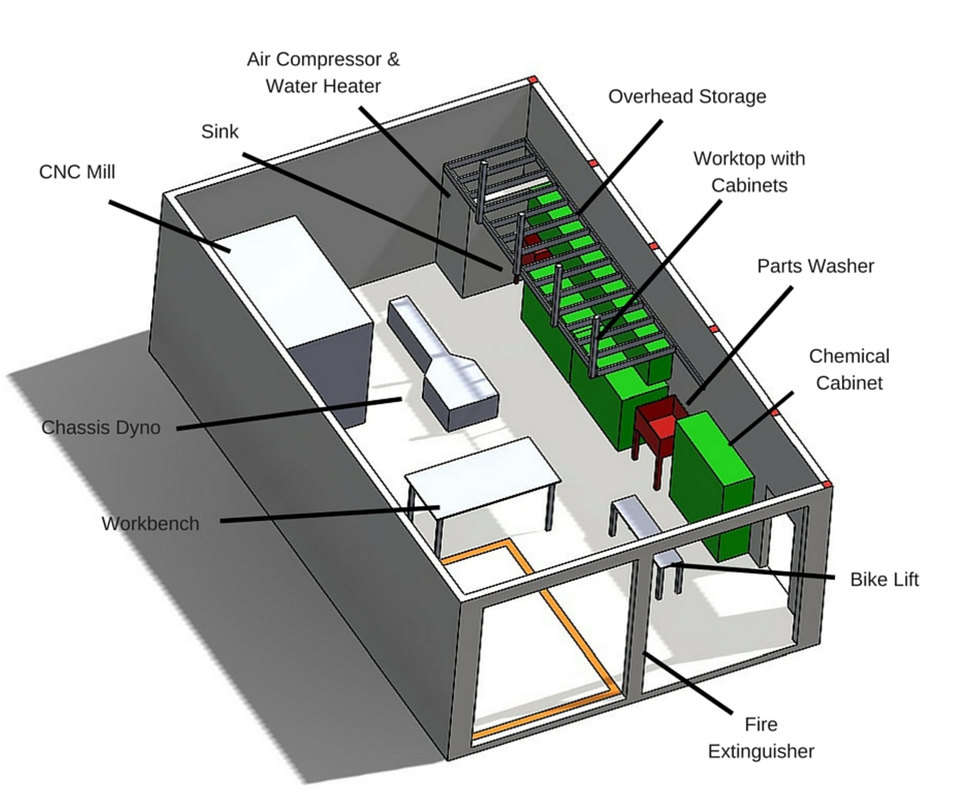

My long term plan is to do all things motorcycle in my shop, including maintaining bikes, rebuilding engines, tuning engines, making engines from scratch, casting parts, machining parts, doing fiberglass work, building frames, and restoring the occasional vintage bike. Yes, I realize I may need to add on!

The Workshop Floor plan

Workshop Lighting

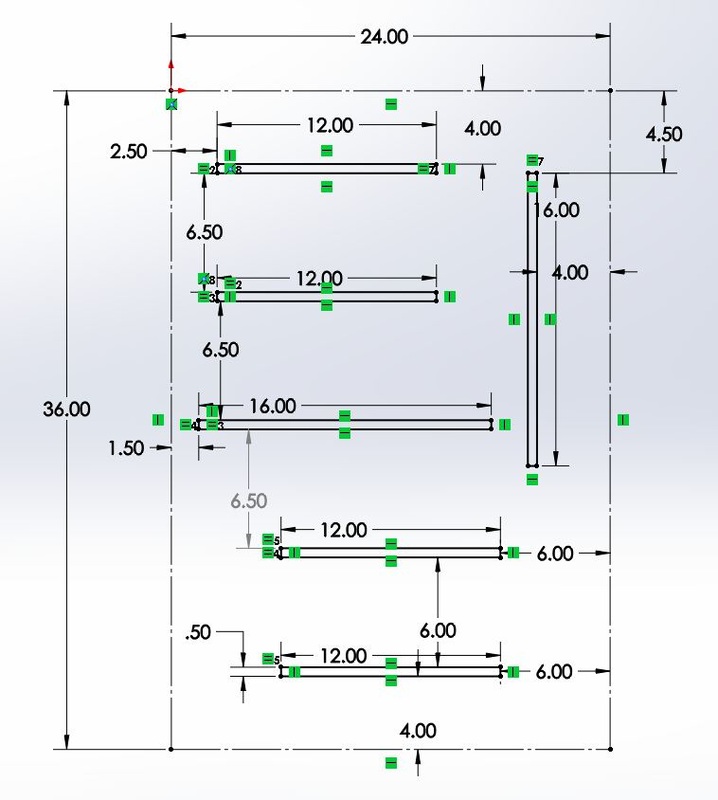

To determine the number of lights needed, a combination of past experience, intuition, and online calculators were used. I ended up needing 20 light fixtures and got them at Lowes where I was able to get 10 bucks off per fixture for ordering in bulk. Below you can see the layout and spacing I used for planning my light installation.

The Workshop Electrical PLan

The next point of action was installing fans in the center of the shop so that all the warm air will be directed downwards when it gets down in the 15 digits here in Wisconsin. I selected a pair of cheap industrial fans with metal blades which are available at Menards.

Workshop Storage

The Expensive Things

Workshop Security

Taking Action

Shortly after the mezzanine was built I added shelving to it. I went with adjustable industrial supports so that I could tailor the space to my needs. The shelves themselves are simply 2 x 12's cut to length and painted.

The large counter top cabinets were built by my father a number of years ago and relocated to my shop this spring. They're not in perfect shape anymore, but beggars can't be choosers! Similar finds can be found on Craigslist if you don't mind secondhand storage solutions. It's always a good way to save a buck, depending on how important a new set are to you as you plan out your own dream workshop.

I've used other floor cushioning systems before and highly recommend selecting mats that do not have any perforated holes in them. I've used perforated mats previously and they collected dirt, were a pain to clean, and picking up small parts off the floor was problematic.

If you enjoyed this post and are looking for more dirt bike maintenance tips and tricks, subscribe to my eNewsletter by entering your email below!

Sign me up for the eNewsletter!

I'm ready to take my dirt bike knowledge to the next level.