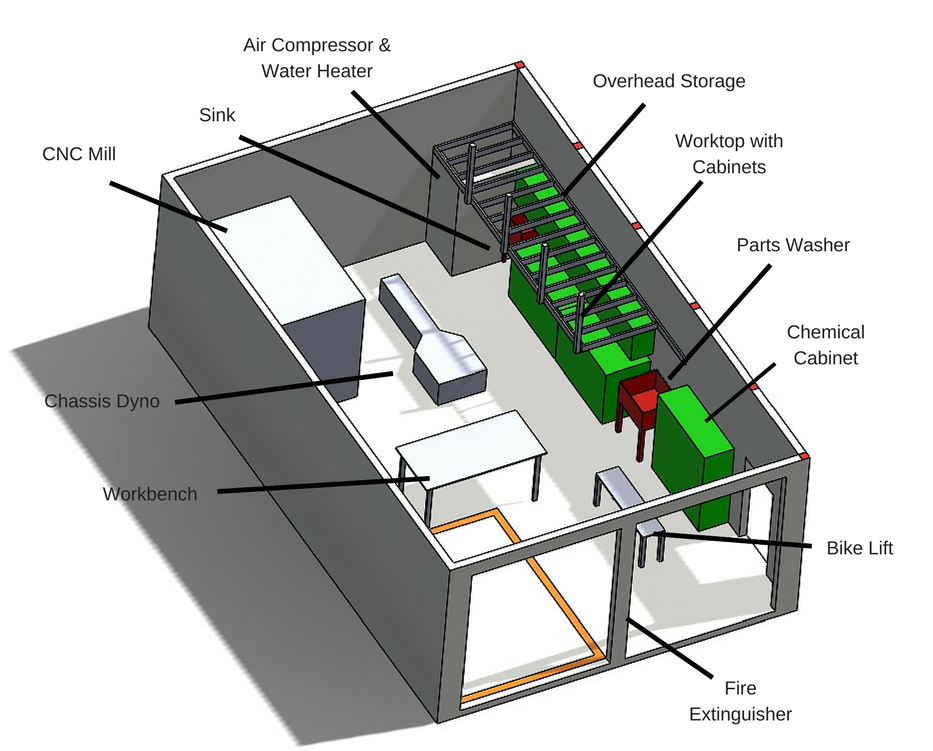

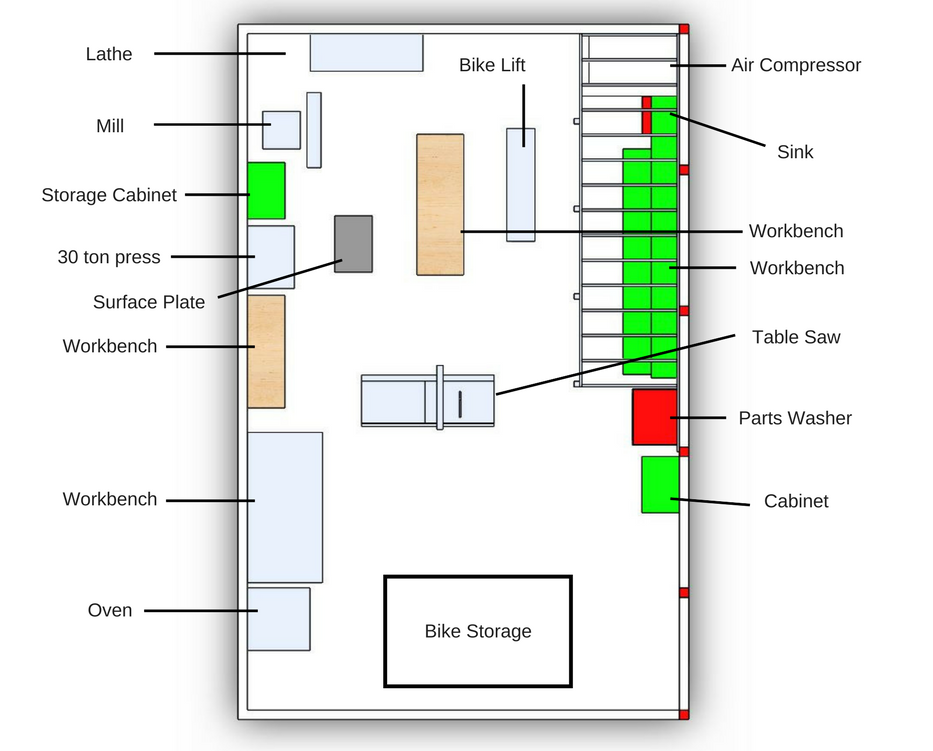

Today, I want to provide an update on the progress I’ve made on setting up my workshop. Overall, 2017 was a good year of growth when it came to acquiring power tools and equipment. The floor plan I originally shared may not ever come to fruition, but I have started to distinctly define certain areas of the shop.

For reference, here’s the original floor plan I came up with:

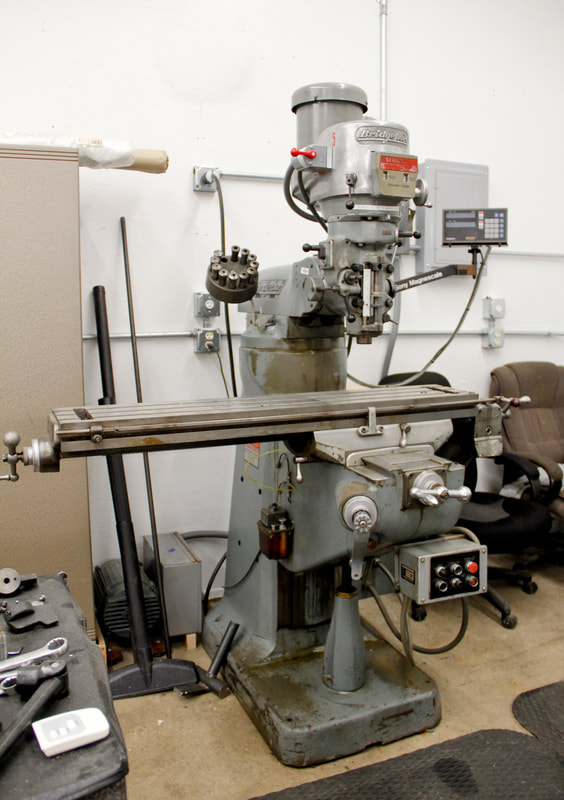

Last fall I bought two machine tools I’ve dreamed about owning for a long time - a mill and a lathe. At a combined weight of around 3800 pounds, picking the mill and lathe up and unloading them was a... fun effort. What I’ve done is put them to the rear of the shop and formed a machining area.

I’ve moved the bike lift to the rear of the shop as well and have it positioned between my wall cabinets and a pair of workbenches. This setup has worked nicely because I can work on the bike and various other parts, all within close proximity.

The front area of the shop is being used primarily for temporary bike storage. This works well because the table saw requires a lot of room when cutting lengthy boards and plywood. I'm also trying to keep the front relatively clear in case I need to pull a four-wheeled vehicle in to work on.

Tools

My arsenal of tools has improved significantly due to necessity, which has resulted from homeownership and supporting my girlfriend’s hobby farm interests. Of course, motorsport related needs have also influenced my priorities! I don’t intend on doing extensive reviews of each piece of equipment, but perhaps for those in the market my comments will be helpful. Typically, there is a large amount of research and reading that takes place prior to me making big purchases. What this boils down to for big purchases is that reading reviews are centric to my purchasing decisions.

Dewalt DW780 Compound Miter Saw - I needed a saw to build “chicken tractors” for my girlfriend. I was down to selecting between a Bosch and the Dewalt and ultimately picked the Dewalt because it had fewer articulating joints and I felt its design would result in better cuts. I picked it up on sale at Home Depot and it came with the free stand. One of the nicest features of the saw is the backlight blade which casts a shadow on the board for cut alignment and doesn’t require calibration. Out of the box it was set up pretty well but I still had to make a few minor adjustments.

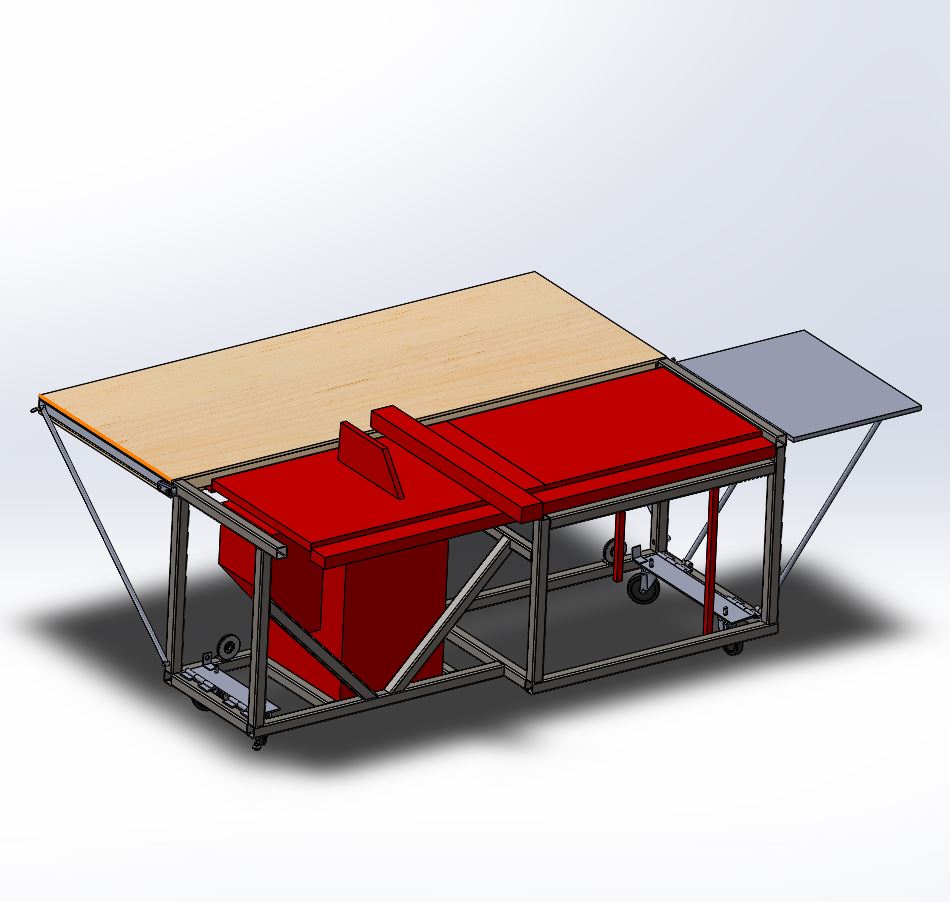

In my efforts to conserve precious shop space I’ve been slowly working on a table saw cabinet design that will enclose the base, and when closed will act as a workbench. The table top can fold down and serve as an outfeed table. On the side of the cabinet is a router table that can be folded down when not in use.

With surgery, all the wiring, and everything else that has been going on I haven’t had much time to actually use the mill. So far I’ve cleaned it up and have been going over all the controls to ensure everything is in good working order. I’ve got several impending projects so 2018 should be a fruitful year of machining.

Supermax air filtration unit - Apart from my shop vac I don’t have a dedicated dust collection system so some dust ends up airborne. I picked up the Supermax unit on a Black Friday sale and have been enjoying much cleaner shop air ever since.

Electrical

With the acquisition of machine tools came wiring upgrades. Both my mill and lathe use 3 phase motors so motor conversions to single phase or a 3 phase electrical solution was required. I opted for the later with the expectation that I may add more three phase equipment in the future. I was able to track down a 7.5 hp rotary phase converter on Craigslist and made the necessary connections. Learning the basics of three phase was interesting and this is definitely an electrical project I think most folks with a basic understanding of electrical stuff could handle.

Thanks for reading!